Toyota Camry (XV70): Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

Before installation of each part, thoroughly clean and dry it. Then apply gear oil to it. Do not use alkaline chemicals to clean aluminum parts, rubber parts or ring gear set bolts. Also, do not use non-residue solvent or other cleaning oils to clean O-rings, oil seals or rubber parts.

PROCEDURE

1. SECURE REAR DIFFERENTIAL CARRIER SUB-ASSEMBLY

(a) Secure the rear differential carrier sub-assembly to the overhaul attachment.

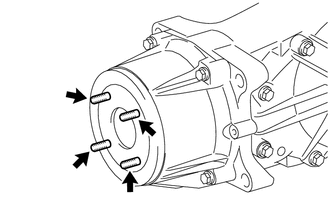

2. REMOVE STUD BOLT

| (a) Using 2 nuts, remove the 4 stud bolts from the transmission coupling assembly. |

|

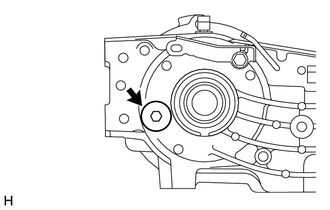

3. REMOVE REAR DIFFERENTIAL FILLER PLUG

| (a) Using a 10 mm socket hexagon wrench, remove the rear differential filler plug and gasket. |

|

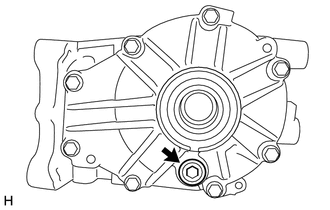

4. REMOVE REAR DIFFERENTIAL DRAIN PLUG

| (a) Using a 10 mm socket hexagon wrench, remove the rear differential drain plug and gasket. |

|

5. REMOVE REAR DIFFERENTIAL CARRIER COVER PLUG

| (a) Using an 8 mm socket hexagon wrench, remove the rear differential carrier cover plug. |

|

6. REMOVE REAR DIFFERENTIAL CARRIER COVER BREATHER PLUG

| (a) Using a chisel and hammer, slightly pry out the rear differential carrier cover breather plug. |

|

(b) Using a screwdriver, lightly pry up and remove the rear differential carrier cover breather plug.

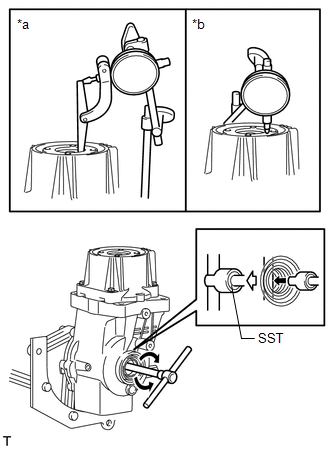

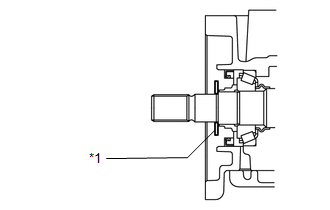

7. INSPECT RUNOUT OF TRANSMISSION COUPLING ASSEMBLY

| (a) Attach a lever probe to a dial indicator and set the probe at a right angle to the inner surface of the transmission coupling assembly. |

|

(b) Using SST, rotate the transmission coupling assembly forward and in reverse and measure the vertical runout.

SST: 09564-32011

Maximum:

0.06 mm (0.00236 in.)

HINT:

If the measurement is more than the maximum, replace the transmission coupling assembly.

(c) Set the dial indicator at a right angle to the transmission coupling assembly in the position shown in the illustration.

(d) Using SST, rotate the transmission coupling assembly forward and in reverse and measure the lateral runout.

SST: 09564-32011

Maximum:

0.07 mm (0.00276 in.)

HINT:

If the measurement is more than the maximum, replace the transmission coupling assembly.

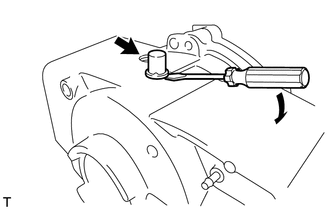

8. REMOVE TRANSMISSION COUPLING ASSEMBLY

| (a) Remove the 4 bolts, and, using a brass bar and hammer, lightly tap the transmission coupling assembly to remove it from the rear differential carrier assembly. NOTICE:

HINT: To prevent the transmission coupling assembly from falling, leave 2 of the bolts screwed in by 5 or 6 threads. |

|

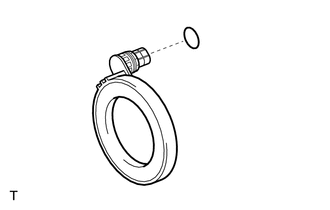

| (b) Using a snap ring expander, remove the snap ring. |

|

| (c) Remove the 4WD linear solenoid from the yoke. |

|

| (d) Remove the O-ring from the 4WD linear solenoid. |

|

| (e) Using a 5 mm socket hexagon wrench, remove the 2 bolts and the yoke from the rear differential carrier sub-assembly. |

|

9. REMOVE TRANSMISSION COUPLING CONICAL SPRING WASHER

| (a) Remove the transmission coupling conical spring washer from the rear differential carrier sub-assembly. |

|

10. REMOVE TRANSMISSION COUPLING SHIM

| (a) Remove the transmission coupling shim from the rear differential carrier sub-assembly. |

|

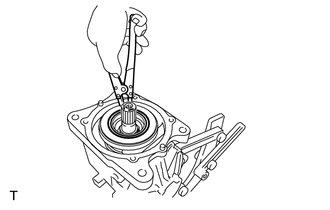

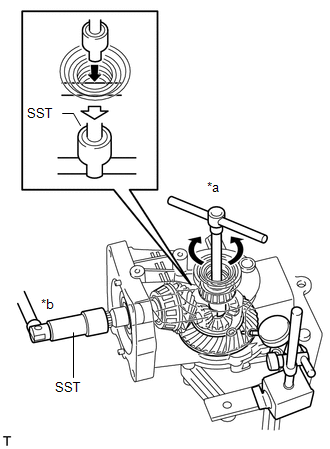

11. INSPECT DIFFERENTIAL RING GEAR BACKLASH

| (a) Insert a dial indicator into the rear differential side gear shaft oil seal hole, and place it perpendicular to the edge of a ring gear tooth. |

|

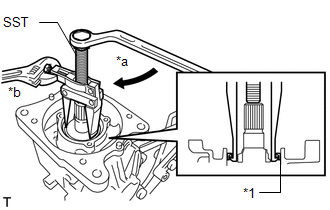

(b) Using SST, secure the differential drive pinion.

SST: 09556-52010

(c) Using SST, check the backlash while rotating the rear differential case sub-assembly forward and in reverse.

SST: 09564-32011

Standard:

0.088 to 0.208 mm (0.00347 to 0.00818 in.)

NOTICE:

Measure the ring gear at 3 or more locations.

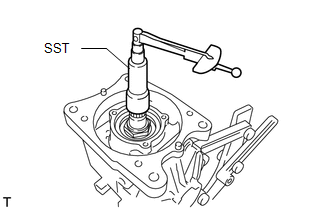

12. INSPECT DIFFERENTIAL DRIVE PINION PRELOAD

| (a) Using SST and a torque wrench, measure the preload (starting torque) of the backlash between the differential drive pinion and differential ring gear. SST: 09556-52010 Standard: 0.77 to 1.26 N*m (8 to 12 kgf*cm, 7 to 11 in.*lbf) |

|

13. INSPECT TOTAL PRELOAD

| (a) Using SST and a torque wrench, measure the preload (at the start of torque) with the teeth of the drive pinion and differential ring gear in contact. SST: 09556-52010 Standard: Total preload = drive pinion preload + 0.58 to 1.01 N*m (6 to 10 kgf*cm, 5 to 8 in.*lbf) NOTICE: Measure the preload after rotating the case bearing several times in the forward and reverse directions to make sure the bearing is operating correctly. |

|

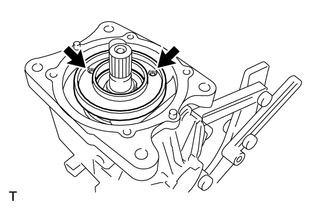

14. REMOVE REAR DRIVE SHAFT OIL SEAL RH

| (a) Using SST, remove the rear drive shaft oil seal RH from the rear differential carrier sub-assembly. SST: 09308-00010 |

|

15. REMOVE REAR DRIVE SHAFT OIL SEAL LH

HINT:

Perform the same procedure as for the RH side.

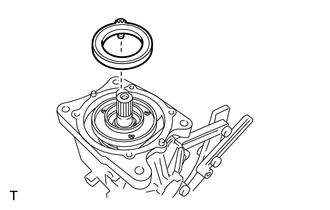

16. REMOVE DIAPHRAGM OIL SEAL

| (a) Using SST, remove the diaphragm oil seal from the rear differential carrier sub-assembly. SST: 09308-10010 |

|

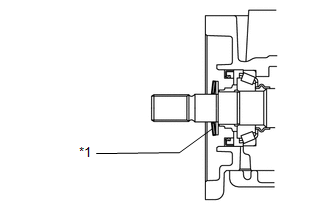

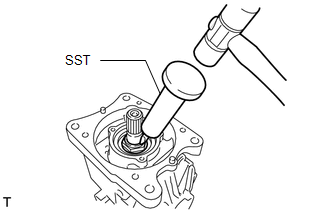

17. REMOVE REAR DRIVE PINION NUT

| (a) Using SST and a hammer, loosen the staked part of the rear drive pinion nut. SST: 09930-00010 NOTICE:

|

|

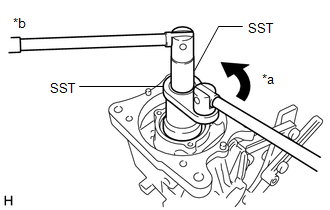

| (b) Using SST, secure the differential drive pinion and remove the rear drive pinion nut from the differential drive pinion. SST: 09556-52010 SST: 09564-16020 |

|

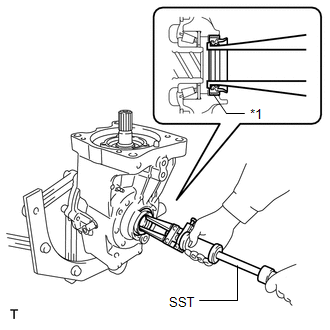

18. REMOVE REAR DRIVE PINION FRONT BEARING

| (a) Using SST, remove the rear drive pinion front tapered roller bearing (inner race) from the rear differential carrier sub-assembly. SST: 09556-30010 |

|

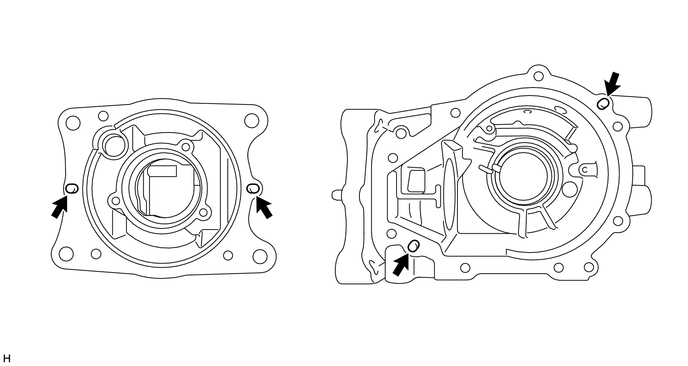

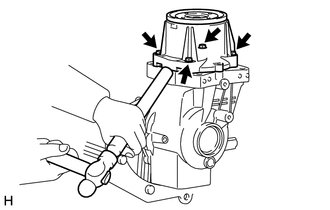

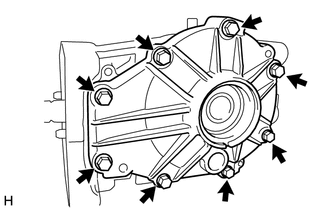

19. REMOVE DIFFERENTIAL SIDE BEARING RETAINER

| (a) Remove the 8 bolts. |

|

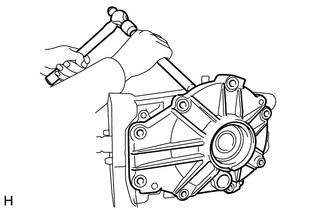

| (b) Using a brass bar and hammer, lightly tap the differential side bearing retainer and remove it. NOTICE:

HINT: Prevent the differential side bearing retainer from falling by screwing in 2 bolts by 5 or 6 threads. |

|

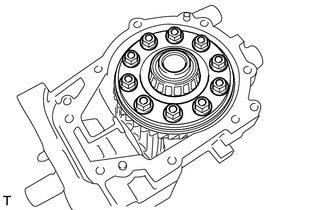

20. REMOVE REAR DIFFERENTIAL CASE SUB-ASSEMBLY

| (a) Remove the rear differential case sub-assembly from the rear differential carrier sub-assembly. |

|

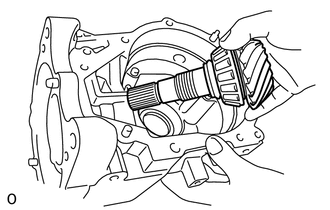

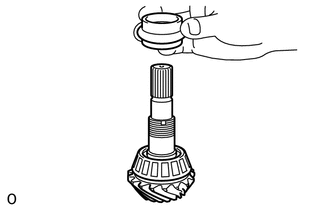

21. REMOVE DIFFERENTIAL DRIVE PINION

| (a) Remove the differential drive pinion from the rear differential carrier sub-assembly. NOTICE: If either the rear differential drive pinion or the differential ring gear has been scratched, replace both. |

|

22. REMOVE REAR DIFFERENTIAL DRIVE PINION BEARING SPACER

| (a) Remove the rear differential drive pinion bearing spacer from the differential drive pinion. |

|

23. REMOVE REAR DRIVE PINION REAR BEARING

| (a) Using SST and a press, remove the rear drive pinion rear tapered roller bearing (inner race) from the differential drive pinion. SST: 09950-00020 NOTICE: If the rear differential driver pinion or differential ring gear is damaged, replace them both. |

|

(b) Remove the rear differential drive pinion washer.

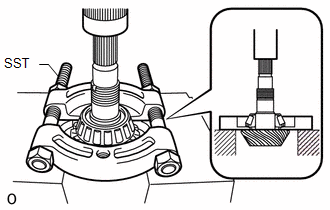

24. REMOVE REAR DRIVE PINION FRONT BEARING

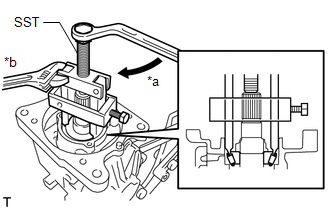

| (a) Attach the claws of SST to the rear drive pinion front tapered roller bearing (outer race) from the notches in the differential carrier sub-assembly. SST: 09612-65014 09612-01020 09612-01050 |

|

(b) Using SST, remove the rear drive pinion front tapered roller bearing (outer race) from the rear differential carrier sub-assembly.

SST: 09612-65014

09612-01020

09612-01050

25. REMOVE REAR DRIVE PINION REAR BEARING

| (a) Using a brass bar and hammer, uniformly lightly tap the rear drive pinion rear tapered roller bearing (outer race) and remove it. NOTICE: Put the brass bar into one of the notches. |

|

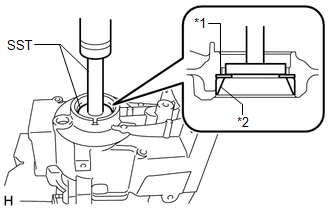

26. REMOVE REAR DIFFERENTIAL CASE BEARING RH

| (a) Using SST and a press, remove the rear differential case bearing RH (outer race) and rear differential side gear shaft washer from the rear differential carrier sub-assembly. SST: 09950-60011 09951-00510 SST: 09950-70010 09951-07100 |

|

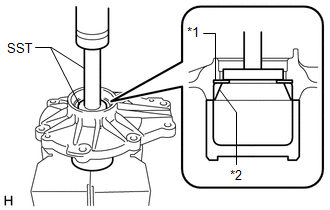

27. REMOVE REAR DIFFERENTIAL CASE BEARING LH

| (a) Using SST and a press, remove the rear differential case bearing LH (outer race) and rear differential side gear shaft washer from the differential side bearing retainer. SST: 09950-60011 09951-00460 SST: 09950-70010 09951-07100 SST: 09649-17010 |

|

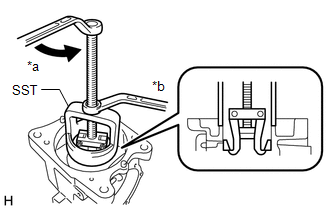

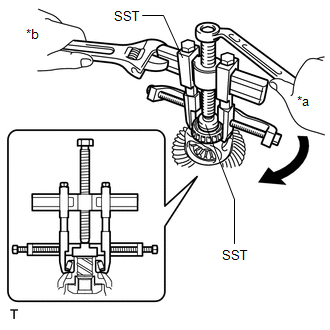

28. REMOVE REAR DIFFERENTIAL CASE BEARING RH

| (a) Using SST, remove the rear differential case bearing RH (inner race) from the rear differential case sub-assembly. SST: 09950-40011 09951-04010 09952-04010 09953-04020 09954-04010 09955-04061 09957-04010 09958-04011 SST: 09950-60011 09951-00320 NOTICE: Before using SST center bolt (09953-04020), apply oil to its threads and tip. HINT:

|

|

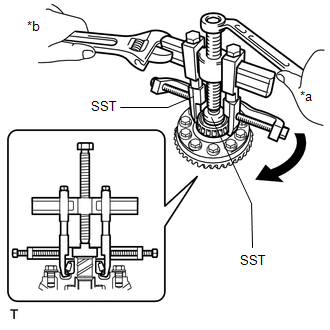

29. REMOVE REAR DIFFERENTIAL CASE BEARING LH

| (a) Using SST, remove the rear differential case bearing LH (inner race) from the rear differential case sub-assembly. SST: 09950-40011 09951-04010 09952-04010 09953-04020 09954-04010 09955-04071 09957-04010 09958-04011 SST: 09950-60011 09951-00320 NOTICE: Before using SST center bolt (09953-04020), apply oil to its threads and tip. HINT:

|

|

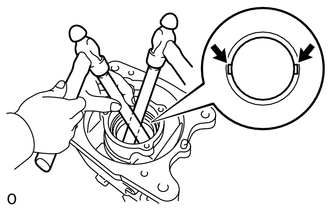

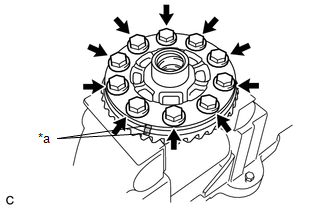

30. REMOVE DIFFERENTIAL RING GEAR

| (a) Mount the rear differential case sub-assembly in a vise between aluminum plates. NOTICE: Do not overtighten the vise. |

|

(b) Put matchmarks on the rear differential case sub-assembly and differential ring gear.

(c) Remove the 10 rear differential case bolts.

(d) Using a plastic-faced hammer, lightly tap the periphery of the differential ring gear to remove it from the rear differential case sub-assembly.

HINT:

Place a cloth on the teeth side of the ring gear to prevent damage.

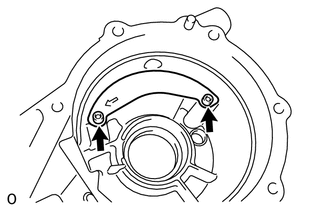

31. REMOVE REAR DIFFERENTIAL BREATHER PLUG OIL DEFLECTOR

| (a) Using a 5 mm socket hexagon wrench, remove the 2 bolts and rear differential breather plug oil deflector. |

|

32. REMOVE STRAIGHT PIN

(a) Remove the 4 straight pins from the rear differential carrier sub-assembly.