Toyota Camry (XV70): Installation

INSTALLATION

PROCEDURE

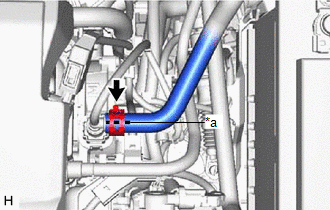

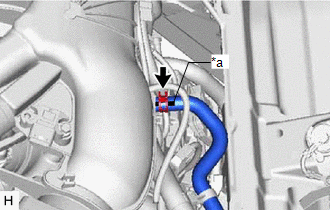

1. INSTALL NO. 1 VACUUM HOSE CONNECTOR (for A25A-FKS)

(a) Align the No. 1 vacuum hose connector with the vacuum pump assembly, and push them together until the No. 1 vacuum hose connector makes a "click" sound.

NOTICE:

- Check that there is no foreign matter on the connecting parts.

- After connecting the No. 1 vacuum hose connector, check that the vacuum pump assembly and No. 1 vacuum hose connector are securely connected by pulling on them.

(b) Connect the vacuum hose to the No. 1 vacuum hose connector.

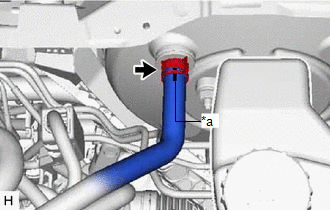

2. INSTALL UNION TO CHECK VALVE HOSE (for A25A-FKS)

(a) Install the 2 clips to the union to check valve hose.

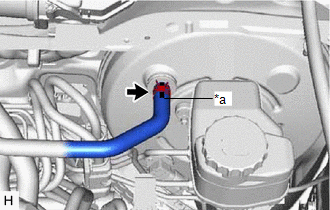

| (b) Connect the union to check valve hose to the No. 1 vacuum hose connector, and slide the clip to secure it. NOTICE:

|

|

| (c) Connect the union to check valve hose to the brake booster assembly, and slide the clip to secure it. NOTICE:

|

|

3. INSTALL AIR TUBE (for 2GR-FKS)

| (a) Engage the clamp to install the air delivery way to the intake air surge tank assembly. |

|

(b) Install the 2 clips to the air tube.

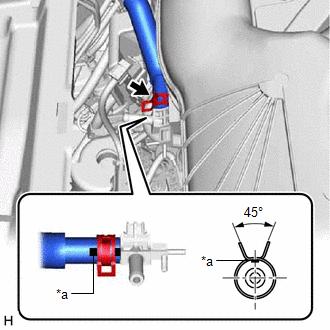

| (c) Connect the air tube to the air delivery way, and slide the clip to secure it. NOTICE:

|

|

| (d) Connect the air tube to the vacuum pump assembly, and slide the clip to secure it. NOTICE:

|

|

| (e) Connect the 2 vacuum transmitting hose assemblies to the air delivery way. |

|

4. INSTALL UNION TO CHECK VALVE HOSE (for 2GR-FKS)

(a) Install the 2 clips to the union to check valve hose.

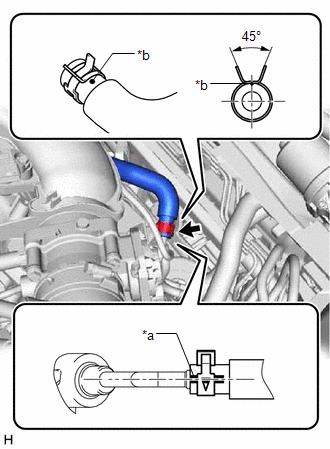

| (b) Connect the union to check valve hose to the air delivery way, and slide the clip to secure it. NOTICE:

|

|

| (c) Connect the union to check valve hose to the brake booster assembly, and slide the clip to secure it. NOTICE:

|

|

| (d) Engage the clamp to install the union to check valve hose to the air tube. |

|

5. INSTALL FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY (for 2GR-FKS)

Click here .gif)

.gif)

.gif)

6. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY (for 2GR-FKS)

Click here

.gif)

.png)

.png)

.png)