Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during brake booster assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Disconnect cable from negative battery terminal |

Perform steering sensor zero point calibration |

Lane tracing assist system |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

|

CAUTION / NOTICE / HINT

NOTICE:

Make sure to release vacuum from the brake booster assembly before removing the brake master cylinder sub-assembly from the brake booster assembly.

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here .gif)

2. REMOVE BRAKE MASTER CYLINDER SUB-ASSEMBLY

Click here .gif)

3. REMOVE NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

Click here .gif)

4. REMOVE COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

Click here .gif)

5. REMOVE FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY

Click here .gif)

6. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY (for A25A-FKS)

Click here .gif)

.gif)

7. REMOVE AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE (for A25A-FKS)

Click here .gif)

.gif)

8. REMOVE AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE (for 2GR-FKS)

Click here .gif)

.gif)

.gif)

9. REMOVE BATTERY CLAMP SUB-ASSEMBLY

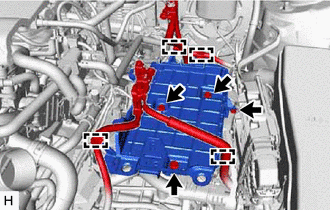

(a) for A25A-FKS:

| (1) Disengage the 4 clamps from the battery clamp sub-assembly. |

|

(2) Remove the 3 bolts, nut and battery clamp sub-assembly.

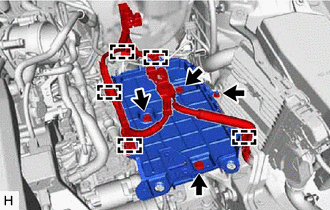

(b) for 2GR-FKS:

| (1) Disengage the 5 clamps from the battery clamp sub-assembly. |

|

(2) Remove the 3 bolts, nut and battery clamp sub-assembly.

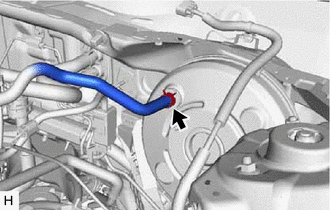

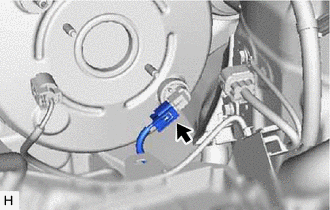

10. DISCONNECT UNION TO CHECK VALVE HOSE

| (a) Slide the clip and disconnect the union to check valve hose from the brake booster assembly. |

|

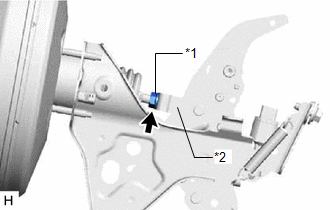

11. LOOSEN LOCK NUT

| (a) Loosen the lock nut of the brake master cylinder push rod clevis. |

|

12. REMOVE PUSH ROD PIN

Click here

.gif)

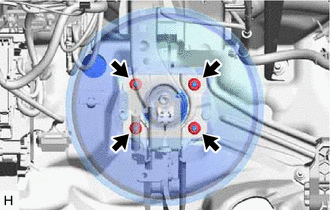

13. REMOVE BRAKE BOOSTER ASSEMBLY

| (a) Disconnect the connector from the vacuum warning switch assembly. |

|

| (b) Remove the 4 nuts and push the brake booster assembly toward the engine compartment. NOTICE: Do not apply excessive force to the brake lines. |

|

(c) Remove the brake master cylinder push rod clevis and lock nut from the brake booster assembly.

(d) Remove the brake booster assembly from the vehicle body.

NOTICE:

Do not apply excessive force to the brake lines.

14. REMOVE BRAKE BOOSTER GASKET