Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during front axle hub sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Front wheel alignment adjustment |

Perform system variant learning and acceleration sensor zero point calibration. |

| w/ Electric Parking Brake System:

w/o Electric Parking Brake System:

|

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

Click here

.gif)

2. REMOVE FRONT AXLE SHAFT NUT

for A25A-FKS: Click here .gif)

for 2GR-FKS: Click here

.gif)

3. SEPARATE FRONT SPEED SENSOR

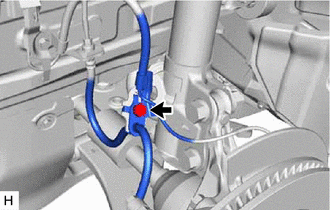

| (a) Remove the bolt and separate the front speed sensor and front flexible hose from the front shock absorber assembly. NOTICE: Be sure to separate the front speed sensor and front flexible hose from the front shock absorber assembly completely. |

|

| (b) Remove the bolt, disengage the clamp and separate the front speed sensor from the front shock absorber assembly and steering knuckle. NOTICE:

|

|

4. SEPARATE TIE ROD ASSEMBLY

Click here

.gif)

5. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY

Click here .gif)

6. REMOVE FRONT DISC

except 2-Pot Caliper: Click here .gif)

for 2-Pot Caliper: Click here .gif)

7. SEPARATE FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY

| (a) Remove the bolt and 2 nuts and separate the front lower No. 1 suspension arm sub-assembly from the front lower ball joint assembly. |

|

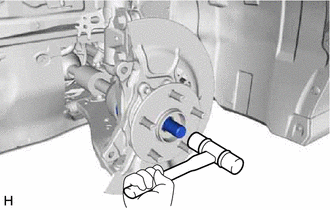

8. SEPARATE FRONT DRIVE SHAFT ASSEMBLY

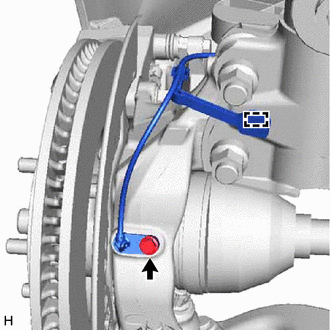

| (a) Put matchmarks on the front drive shaft assembly and the front axle hub sub-assembly. |

|

| (b) Using a plastic hammer, separate the front drive shaft assembly from the front axle assembly. NOTICE:

HINT: If it is difficult to separate the front drive shaft assembly from the front axle assembly, tap the end of the front drive shaft assembly using a brass bar and a hammer. |

|

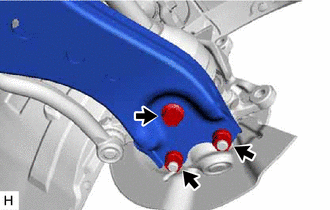

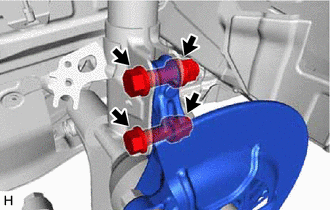

9. REMOVE FRONT AXLE ASSEMBLY

| (a) Remove the 2 bolts, 2 nuts and front axle assembly from the front shock absorber assembly. NOTICE: When removing the nuts, keep the bolts from rotating. |

|

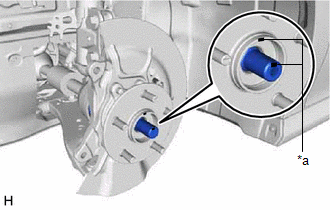

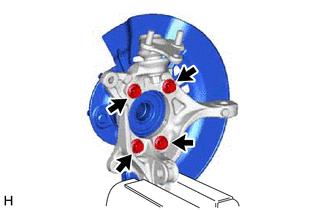

10. REMOVE FRONT AXLE HUB SUB-ASSEMBLY

| (a) Secure the front axle assembly between aluminum plates in a vise. NOTICE: Do not overtighten the vise. |

|

(b) Remove the 4 bolts, front axle hub sub-assembly and front disc brake dust cover from the steering knuckle.

NOTICE:

- Do not drop the front axle hub sub-assembly.

- Be careful not to damage the speed sensor rotor or contact surfaces.

- Do not allow foreign matter to contact the speed sensor rotor or contact surfaces.