Toyota Camry (XV70): Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during transfer case oil seal RH removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Electric Parking Brake System

*2: w/o Electric Parking Brake System | |||

|

Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Front wheel alignment adjustment |

|

|

|

PROCEDURE

1. REMOVE FRONT WHEEL OPENING EXTENSION PAD RH

Click here

.gif)

.gif)

2. REMOVE FRONT WHEEL OPENING EXTENSION PAD LH

Click here

.gif)

.gif)

3. REMOVE NO. 1 ENGINE UNDER COVER

Click here

.gif)

.gif)

4. REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY

Click here

.gif)

.gif)

5. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

Click here

.gif)

6. REMOVE DRIVE SHAFT BEARING BRACKET

Click here .gif)

.gif)

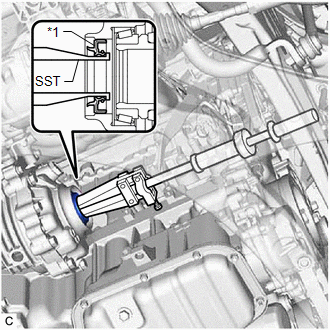

7. REMOVE TRANSFER CASE OIL SEAL RH

| (a) Using SST, remove the transfer case oil seal RH from the transfer assembly. SST: 09308-00010 NOTICE: Do not scratch the press-fitting surface of the transfer case oil seal RH. |

|

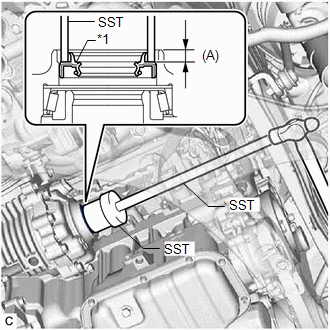

8. INSTALL TRANSFER CASE OIL SEAL RH

(a) Coat the lip of a new transfer case oil seal RH with MP grease.

| (b) Using SST and a hammer, tap in the transfer case oil seal RH to the transfer assembly as shown in the illustration. SST: 09631-32020 SST: 09950-60021 09951-00680 SST: 09950-70010 09951-07360 Drive in depth (A): 7.5 to 8.5 mm (0.296 to 0.334 in.) NOTICE:

|

|

9. INSTALL DRIVE SHAFT BEARING BRACKET

Click here

.gif)

10. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

Click here .gif)

11. INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

12. INSTALL NO. 1 ENGINE UNDER COVER

Click here .gif)

13. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

14. INSTALL FRONT WHEEL OPENING EXTENSION PAD RH

Click here .gif)