Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT DRIVE SHAFT ASSEMBLY

| (a) Check that there is no excessive play in the radial direction of the outboard joint. |

|

(b) Check that the inboard joint slides smoothly in the thrust direction.

(c) Check that there is no excessive play in the radial direction of the inboard joint.

(d) Check the boots for damage.

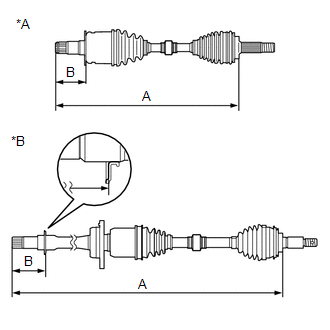

| (e) Check whether the drive shaft dimension (A) and (B) are within specification. NOTICE: Keep the drive shaft assembly level during inspection. Dimension (A):

Dimension (B):

|

| ||||||||||||||||||||||

READ NEXT:

Reassembly

Reassembly

REASSEMBLY CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL FRONT DRIVE SHAFT BEARING (f

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL FRONT DRIVE SHAFT HOLE SNA

SEE MORE:

Shift Paddle Switch Circuit

Shift Paddle Switch Circuit

DESCRIPTION Moving the shift lever to S enables the shift range to be selected. The shift range can be selected by operating the "+" or "-" shift paddle switch. WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE: After turning the engine switch off, waiting time may be required before disconnecting

Software Incompatibility with Body Control Module "B" (U1331)

Software Incompatibility with Body Control Module "B" (U1331)

DESCRIPTION This DTC is stored when the destination information of the main body ECU (multiplex network body ECU) does not match that of the blind spot monitor sensors. Blind Spot Monitor Master

DTC No. Detection Item

DTC Detection Condition Trouble Area

U1331 Software Incom

© 2023-2025 Copyright www.tocamry.com

.png)