Toyota Camry (XV70): Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL PIPE PLUG SUB-ASSEMBLY

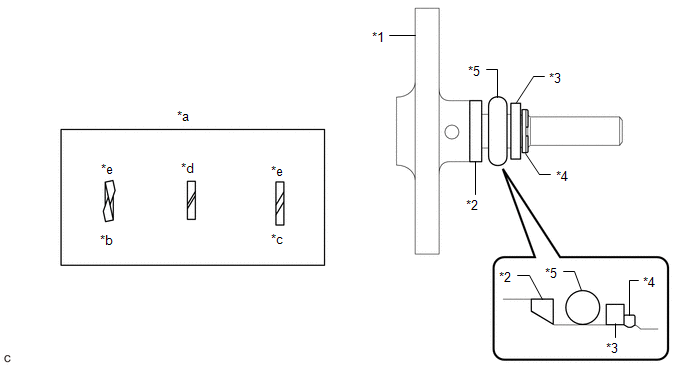

(a) Install a new O-ring, No. 1 fuel injector back-up ring, No. 2 fuel injector back-up ring and No. 3 fuel injector back-up ring to the fuel pipe plug sub-assembly as shown in the illustration.

|

*1 | Fuel Pipe Plug Sub-assembly |

*2 | No. 1 Fuel Injector Back-up Ring |

|

*3 | No. 2 Fuel Injector Back-up Ring |

*4 | No. 3 Fuel Injector Back-up Ring |

|

*5 | O-ring |

- | - |

|

*a | Opening |

*b | Overlapped |

|

*c | Stretched |

*d | Correct |

|

*e | Incorrect |

- | - |

NOTICE:

- Check that there is no foreign matter or damage on the O-ring groove of the fuel pipe plug sub-assembly.

- Check that the No. 1 fuel injector back-up ring and No. 3 fuel injector back-up ring are installed in the correct orientation.

- Make sure that the No. 1 fuel injector back-up ring, No. 2 fuel injector back-up ring, No. 3 fuel injector back-up ring and O-ring are installed in the correct order.

- Check that the opening of the No. 1 fuel injector back-up ring is not overlapped or stretched as shown in the illustration.

- After installing the O-ring, check that it is not contaminated with foreign matter and is not damaged.

(b) w/ Dust Cap:

(1) Install the dust cap sub-assembly to the fuel pipe plug sub-assembly.

| (c) Install a new gasket to the fuel pipe plug sub-assembly as shown in the illustration. |

|

(d) Secure the fuel delivery pipe with sensor assembly LH in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

(e) Using a 5 mm hexagon socket wrench, install the fuel pipe plug sub-assembly to the fuel delivery pipe with sensor assembly LH with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(f) Remove the fuel delivery pipe with sensor assembly LH from the vise.

2. INSTALL FUEL PRESSURE SENSOR (FUEL DELIVERY PIPE WITH SENSOR ASSEMBLY LH)

HINT:

Perform "Inspection After Repair" after replacing the fuel pressure sensor (fuel delivery pipe with sensor assembly LH).

Click here .gif)

.gif)

.gif)

Click here .gif)

NOTICE:

- Do not remove the fuel pressure sensor from the fuel delivery pipe with sensor assembly LH.

- If the fuel pressure sensor is removed, replace the fuel pressure sensor (fuel delivery pipe with sensor assembly LH) with a new one.

3. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the fuel pressure sensor (fuel delivery pipe with sensor assembly LH).

Click here .gif)

.gif)

.gif)