Toyota Camry (XV70): On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE BOOSTER ASSEMBLY

(a) Airtightness check

| (1) Start the engine and stop it after 1 or 2 minutes. Slowly depress the brake pedal several times.

If the brake pedal can be depressed nearly to the floor the first time, but on the 2nd and 3rd time cannot be depressed as far, the brake booster assembly is airtight. |

|

|

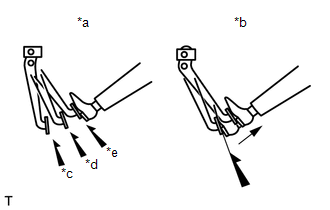

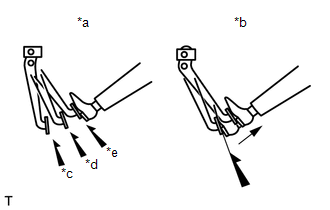

*a | Correct | |

*b | Incorrect | |

*c | 1st | |

*d | 2nd | |

*e | 3rd | | |

(2) Depress the brake pedal with the engine running, and stop the engine with the brake pedal depressed.

If there is no change in the brake pedal reserve distance while holding the brake pedal depressed for 30 seconds, the brake booster assembly is airtight.

(b) Operation check

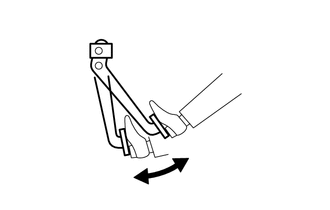

| (1) Depress the brake pedal several times with the ignition switch off and check that there is no change in the brake pedal reserve distance when the brake pedal is depressed. |

|

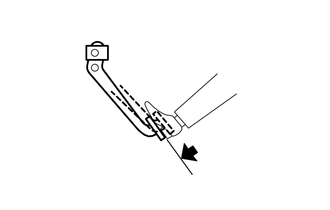

| (2) Depress and hold the brake pedal, then start the engine. If the brake pedal goes down slightly, operation is normal. |

|

READ NEXT:

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during br

DISASSEMBLY PROCEDURE 1. REMOVE BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Remove the brake vacuum check valve assembly from the brake booster assembly.

(b) Remove the check valve grommet from the brak

INSPECTION PROCEDURE 1. INSPECT BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Check that there is ventilation from the booster side to the engine side, and no ventilation from the engine side to the boo

SEE MORE:

ComponentsCOMPONENTS ILLUSTRATION

*1 AIR CLEANER CAP SUB-ASSEMBLY

*2 AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY RemovalREMOVAL PROCEDURE

1. SEPARATE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disengage the 2 wire harness clamps.

(b) Disengage the 2 air cleaner

DESCRIPTION Refer to DTC C051212 Click here

DTC No. Detection Item

DTC Detection Condition Trouble Area

C05121F Right Rear Wheel Speed Sensor Circuit Intermittent

The speed sensor signal is excessively noisy.

The calculated change in wheel speed is more