Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during park/neutral position switch assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

| Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

| ||

|

Replacement of ECM | Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

| |

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

| for Initialization for Registration |

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM |

Code registration |

|

|

NOTICE:

Before removing the park/neutral position switch assembly, check that the shift lever is in N.

PROCEDURE

1. SECURE VEHICLE

(a) Fully apply the parking brake and chock a wheel.

CAUTION:

- Make sure to apply the parking brake and chock a wheel before performing this procedure.

- If the vehicle is not secure and the shift lever is moved to N, the vehicle may suddenly move, possibly resulting in an accident or serious injury.

.png)

2. REMOVE BATTERY

Click here .gif)

3. REMOVE ECM

Click here .gif)

4. REMOVE BATTERY CLAMP SUB-ASSEMBLY

Click here .gif)

.gif)

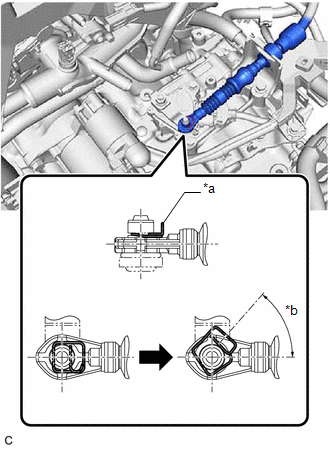

5. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

| (a) While disengaging the clip as shown in the illustration, disconnect the transmission control cable assembly from the transmission control shaft lever together with the clip. |

|