Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during VVT sensor removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Inspection after repair |

|

|

PROCEDURE

1. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

Click here

.gif)

.gif)

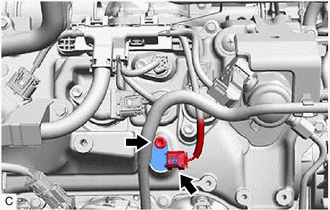

2. REMOVE VVT SENSOR (for Intake Side of Bank 1)

| (a) Disconnect the VVT sensor connector. |

|

(b) Remove the bolt and VVT sensor from the cylinder head cover sub-assembly.

NOTICE:

If the VVT sensor has been struck or dropped, replace it.

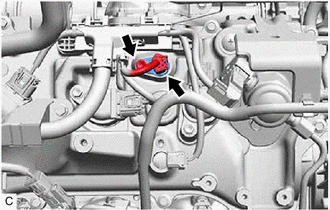

3. REMOVE VVT SENSOR (for Exhaust Side of Bank 1)

| (a) Disconnect the VVT sensor connector. |

|

(b) Remove the bolt and VVT sensor from the cylinder head cover sub-assembly.

NOTICE:

If the VVT sensor has been struck or dropped, replace it.

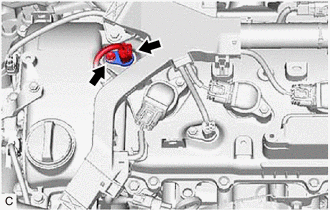

4. REMOVE VVT SENSOR (for Intake Side of Bank 2)

| (a) Disconnect the VVT sensor connector. |

|

(b) Remove the bolt and VVT sensor from the cylinder head cover sub-assembly LH.

NOTICE:

If the VVT sensor has been struck or dropped, replace it.

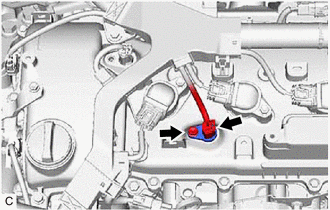

5. REMOVE VVT SENSOR (for Exhaust Side of Bank 2)

| (a) Disconnect the VVT sensor connector. |

|

(b) Remove the bolt and VVT sensor from the cylinder head cover sub-assembly LH.

NOTICE:

If the VVT sensor has been struck or dropped, replace it.