Toyota Camry (XV70): Stop Lamp Relay Actuator Stuck Off (C13807F)

DESCRIPTION

Refer to DTC C13807E.

Click here

.gif)

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

|---|---|---|---|

|

C13807F | Stop Lamp Relay Actuator Stuck Off |

When the voltage at the +BS terminal is between 10 V or more and the stop light control relay (stop light switch assembly) drive output (STPO) is on, a signal is not input to the STP2 terminal for 5 seconds or more. |

|

WIRING DIAGRAM

Refer to DTC C13807E.

Click here

.gif)

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- After replacing the skid control ECU (brake actuator assembly), perform acceleration sensor zero point calibration and system information memorization.

Click here

.gif)

.gif)

HINT:

When DTC P057111, P057112 and/or P057113 are output together with DTC C13807F, inspect and repair the trouble areas indicated by DTC P057111, P057112 and/or P057113 first.

P057111: Click here .gif)

.gif)

P057112: Click here

.gif)

.gif)

P057113: Click here .gif)

.gif)

PROCEDURE

| 1. |

CHECK STOP LIGHT OPERATION |

(a) Check that the stop lights come on when the brake pedal is depressed.

OK:

The stop lights illuminate.

| NG | .gif) | GO TO STEP 6 |

|

| 2. |

PERFORM ACTIVE TEST USING TECHSTREAM (STOP LAMP RELAY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Enter the following menus: Chassis / Brake / Active Test.

Chassis > Brake > Active Test|

Tester Display | Measurement Item |

Control Range | Restrict Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Stop Lamp Relay | Stop light control relay (Stop light switch assembly) |

Relay OFF / ON | Vehicle condition: Vehicle stopped HINT: To protect this Actuator and Solenoid, this test will only last 5 seconds. |

With the brake pedal released, check that the stop lights illuminate and the value of Stop Lamp Relay on the Techstream changes to ON when Stop Lamp Relay is ON |

|

Tester Display |

|---|

| Stop Lamp Relay |

(d) According to the display on the Techstream, perform the Active Test and check the operation of the stop lights.

OK:

Stop lights turn on in accordance with the Active Test.

| NG | .gif) | GO TO STEP 4 |

|

| 3. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SIGNAL INPUT CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

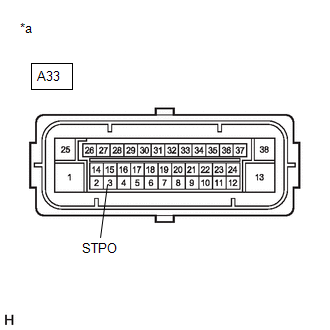

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A33-24 (STP2) - Body ground |

Brake pedal depressed |

11 to 14 V |

| OK | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 4. |

INSPECT STOP LIGHT SWITCH ASSEMBLY (ACC TERMINAL VOLTAGE) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A81-4 (ACC) - Body ground |

Always | 11 to 14 V |

| NG | .gif) | REPLACE STOP LIGHT SWITCH ASSEMBLY |

|

| 5. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A33-3 (STPO) - Body ground |

Always | 11 to 14 V |

| OK | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 6. |

CHECK STOP LIGHT OPERATION |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Check that the stop lights come on when the brake pedal is depressed.

OK:

The stop lights illuminate.

| OK | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

|

| 7. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR COMBINATION LIGHT ASSEMBLY LH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the W13 rear combination light assembly LH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

W13-2 (STP) - Body ground |

Brake pedal depressed |

11 to 14 V |

| OK | .gif) | GO TO LIGHTING SYSTEM (REAR COMBINATION LIGHT ASSEMBLY LH (STOP LIGHT CIRCUIT)) Refer to "Left or right stop light does not illuminate" of problem symptoms table. Click here |

|

| 8. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR COMBINATION LIGHT ASSEMBLY RH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the W13 rear combination light assembly LH connector.

(d) Disconnect the W12 rear combination light assembly RH connector.

(e) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

W12-2 (STP) - Body ground |

Brake pedal depressed |

11 to 14 V |

| OK | .gif) | GO TO LIGHTING SYSTEM (REAR COMBINATION LIGHT ASSEMBLY RH (STOP LIGHT CIRCUIT)) Refer to "Left or right stop light does not illuminate" of problem symptoms table. Click here |

|

| 9. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - CENTER STOP LIGHT SET) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the W13 rear combination light assembly LH connector.

(d) Disconnect the W12 rear combination light assembly RH connector.

(e) Disconnect the R47 center stop light set connector.

(f) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(g) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

R47-1 (B) - Body ground |

Brake pedal depressed |

11 to 14 V |

| OK | .gif) | REPLACE CENTER STOP LIGHT SET |

|

| 10. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR COMBINATION LIGHT ASSEMBLY LH) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the W13 rear combination light assembly LH connector.

(d) Disconnect the W12 rear combination light assembly RH connector.

(e) Disconnect the R47 center stop light set connector.

(f) Disconnect the A81 stop light switch assembly connector.

(g) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(h) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A81-1 (OUT) - W13-2 (STP) |

Always | Below 1 Ω |

|

A81-1 (OUT) or W13-2 (STP) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)

.png)

.png)

.png)

.png)

.png)