Toyota Camry (XV70): 4wd Control Ecu

Components

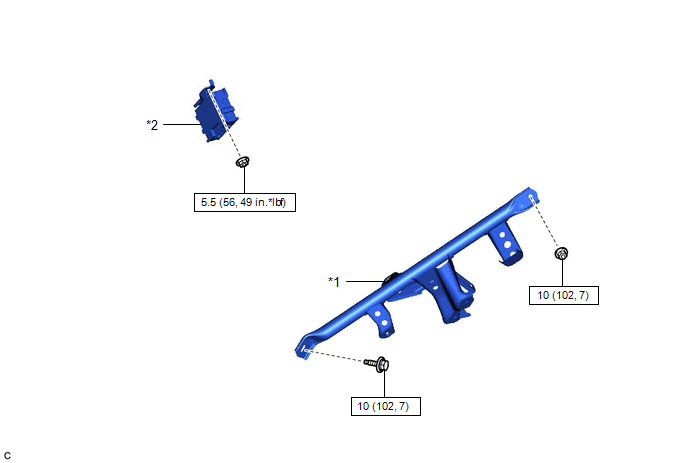

COMPONENTS

ILLUSTRATION

|

*1 | NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY |

*2 | 4WD ECU ASSEMBLY |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during 4WD ECU assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

|

PROCEDURE

1. REMOVE LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

Click here

.gif)

2. REMOVE NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY

Click here .gif)

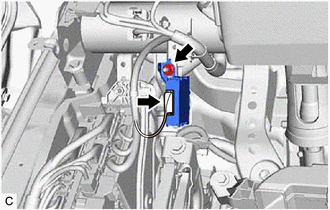

3. REMOVE 4WD ECU ASSEMBLY

(a) Disconnect the 4WD ECU assembly connector.

(b) Remove the nut and 4WD ECU assembly from the instrument panel reinforcement assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL 4WD ECU ASSEMBLY

(a) Install the 4WD ECU assembly to the instrument panel reinforcement assembly with the nut.

Torque:

5.5 N