Toyota Camry (XV70): Brake Switch "B" Circuit Short to Battery (P070312)

DESCRIPTION

The purpose of the stop light switch signal circuit is to prevent the engine from stalling when the brakes are suddenly applied while driving in the lock-up condition.

When the brake pedal is depressed, the stop light switch assembly sends a signal to the ECM. The ECM then cancels the operation of the lock-up clutch while braking is in progress.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

MIL | Memory |

Note |

|---|---|---|---|---|---|---|

| P070312 |

Brake Switch "B" Circuit Short to Battery |

All of the following conditions are met (2-trip detection logic):

|

| Comes on |

DTC stored | SAE Code: P0724 |

MONITOR DESCRIPTION

This DTC indicates that the stop light switch is remaining on. When the stop light switch remains on during GO and STOP driving, the ECM interprets this as a malfunction of the stop light switch assembly, illuminates the MIL and stores this DTC. The vehicle must GO (30 km/h (19 mph) or more) and STOP (less than 3 km/h (2 mph)) 5 times for 2 consecutive driving cycles in order for this DTC to be stored.

MONITOR STRATEGY

|

Related DTCs | P0724: Stop light switch/Verify switch input |

|

Required sensors/components | Stop light switch assembly |

|

Frequency of operation | Continuous |

|

Duration | GO and STOP 5 times |

|

MIL operation | 2 driving cycles |

|

Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

The stop light switch remains on during GO and STOP driving 5 times.

GO and STOP are defined as follows:

|

The monitor will run whenever the following DTCs are not stored |

None |

| GO (Vehicle speed is 30 km/h (18.65 mph) or more) |

Once |

| STOP (Vehicle speed is less than 3 km/h (1.86 mph)) |

Once |

| Battery voltage |

8 V or more |

| Engine switch |

On (IG) |

| Starter |

OFF |

TYPICAL MALFUNCTION THRESHOLDS

|

Stop light switch | ON |

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the Clear Permanent DTC procedure.

Click here

.gif)

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG) and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the engine switch off and wait for 2 minutes or more.

- Turn the engine switch on (IG) and turn the Techstream on.

- Start the engine.

- Repeat the following procedure 5 times [*1]:

- Accelerate the vehicle to 30 km/h (19 mph) or more, depress the brake pedal and decelerate the vehicle to 3 km/h (2 mph) or less.

HINT:

[*1] : Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Accelerate the vehicle to 30 km/h (19 mph) or more, depress the brake pedal and decelerate the vehicle to 3 km/h (2 mph) or less.

- Stop the vehicle.

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P070312.

- Check the DTC judgment result.

Techstream Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to SFI system DTC P05042B.

Click here .gif)

.gif)

.gif)

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Perform the universal trip to clear permanent DTCs.

Click here

.gif)

- Perform registration and/or initialization when parts related to the automatic transaxle are replaced.

Click here

.gif)

.gif)

.gif)

DATA LIST

NOTICE:

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

HINT:

Using the Techstream to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

(a) Warm up the engine.

(b) Turn the engine switch off.

(c) Connect the Techstream to the DLC3.

(d) Turn the engine switch on (IG).

(e) Turn the Techstream on.

(f) Enter the following menus: Powertrain / Transmission / Data List / Stop Light SW.

(g) Read the Data List according to the display on the Techstream.

Powertrain > Transmission > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Stop Light SW | Stop light switch status |

ON or OFF |

| - |

|

Tester Display |

|---|

| Stop Light SW |

PROCEDURE

| 1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Transmission / Data List / Stop Light SW.

(e) Read the Data List according to the display on the Techstream.

Powertrain > Transmission > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Stop Light SW | Stop light switch status |

ON or OFF |

| - |

|

Tester Display |

|---|

| Stop Light SW |

|

Result | Proceed to |

|---|---|

|

Data List value is normal |

A |

| Data List value is not normal |

B |

| A |

.gif) | SYMPTOM SIMULATION AND DTC CHECK

|

|

| 2. |

CHECK STOP LIGHT SWITCH ASSEMBLY INSTALLATION |

(a) Check the stop light switch assembly installation condition.

Click here

.gif)

OK:

Stop light switch assembly is installed correctly.

| NG | .gif) | REINSTALL STOP LIGHT SWITCH ASSEMBLY CORRECTLY |

|

| 3. |

INSPECT STOP LIGHT SWITCH ASSEMBLY |

(a) Inspect the stop light switch assembly.

Click here .gif)

.gif)

.gif)

| NG | .gif) | REPLACE STOP LIGHT SWITCH ASSEMBLY |

|

| 4. |

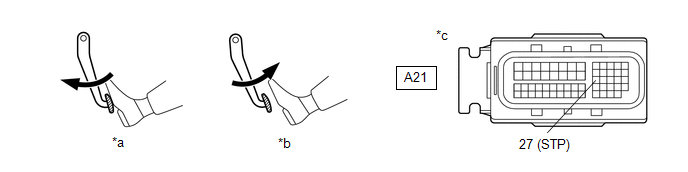

CHECK TERMINAL VOLTAGE (STP VOLTAGE) |

(a) Disconnect the A21 ECM connector.

|

*a | Brake pedal depressed |

*b | Brake Pedal Released |

|

*c | Front view of wire harness connector (to ECM) |

- | - |

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A21-27 (STP) - Body ground |

Brake pedal released |

Below 1.5 V |

|

Brake pedal depressed |

7.5 to 14 V |

HINT:

If there is a short in the STP terminal circuit, there may be a malfunction in the circuit of a connected ECU.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - ECM) |

|

| 5. |

REPLACE ECM |

(a) Replace the ECM.

Click here .gif)

.gif)

.gif)

| NEXT | .gif) | PERFORM REGISTRATION |

.gif)