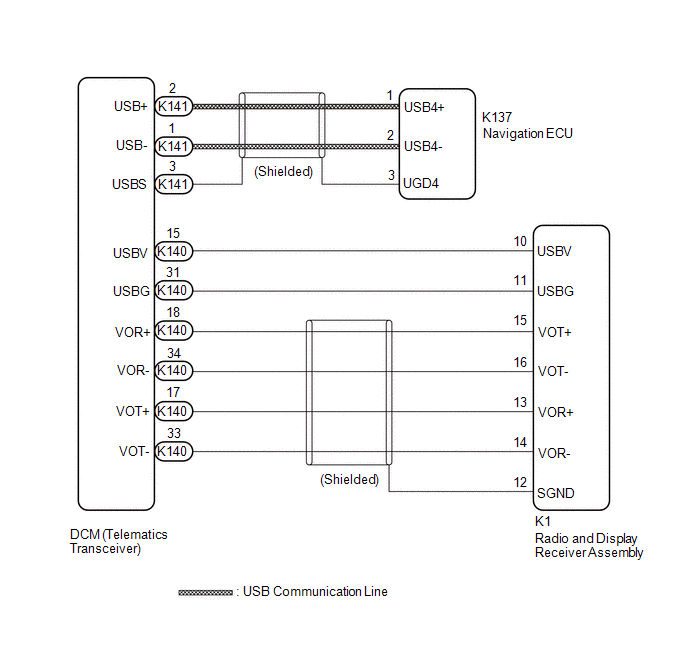

Toyota Camry (XV70): DCM Data Signal Circuit between Navigation ECU and DCM

DESCRIPTION

This circuit is used to send and receive signals between the DCM (Telematics Transceiver) and radio and display receiver assembly or navigation ECU.

WIRING DIAGRAM

PROCEDURE

| 1. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - DCM (TELEMATICS TRANSCEIVER)) |

(a) Disconnect the K140 DCM (Telematics Transceiver) connector.

(b) Disconnect the K1 radio and display receiver assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K140-31 (USBG) - K1-11 (USBG) |

Always | Below 1 Ω |

|

K140-17 (VOT+) - K1-13 (VOR+) |

Always | Below 1 Ω |

|

K140-15 (USBV) - K1-10 (USBV) |

Always | Below 1 Ω |

|

K140-33 (VOT-) - K1-14 (VOR-) |

Always | Below 1 Ω |

|

K140-34 (VOR-) - K1-16 (VOT-) |

Always | Below 1 Ω |

|

K140-18 (VOR+) - K1-15 (VOT+) |

Always | Below 1 Ω |

|

K140-31 (USBG) or K1-11 (USBG) - Body ground |

Always | 10 kΩ or higher |

|

K140-17 (VOT+) or K1-13 (VOR+) - Body ground |

Always | 10 kΩ or higher |

|

K140-15 (USBV) or K1-10 (USBV) - Body ground |

Always | 10 kΩ or higher |

|

K140-33 (VOT-) or K1-14 (VOR-) - Body ground |

Always | 10 kΩ or higher |

|

K140-34 (VOR-) or K1-16 (VOT-) - Body ground |

Always | 10 kΩ or higher |

|

K140-18 (VOR+) or K1-15 (VOT+) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 2. |

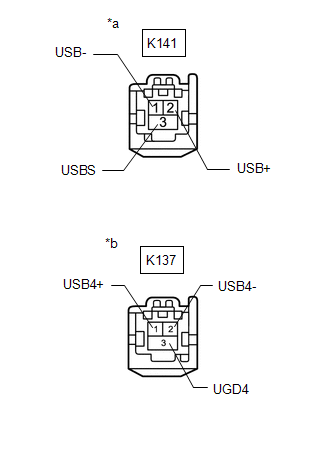

CHECK HARNESS AND CONNECTOR (NAVIGATION ECU - DCM (TELEMATICS TRANSCEIVER)) |

| (a) Disconnect the K141 DCM (Telematics Transceiver) connector. |

|

(b) Disconnect the K137 navigation ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K141-1 (USB-) - K137-2 (USB4-) |

Always | Below 1 Ω |

|

K141-2 (USB+) - K137-1 (USB4+) |

Always | Below 1 Ω |

|

K141-3 (USBS) - K137-3(UGD4) |

Always | Below 1 Ω |

|

K141-1 (USB-) or K137-2 (USB4-) - Body ground |

Always | 10 kΩ or higher |

|

K141-2 (USB+) or K137-1 (USB4+) - Body ground |

Always | 10 kΩ or higher |

|

K141-3 (USBS) or K137-3 (UGD4) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)