Toyota Camry (XV70): Precaution

PRECAUTION

BASIC REPAIR HINT

(a) HINTS ON OPERATIONS

|

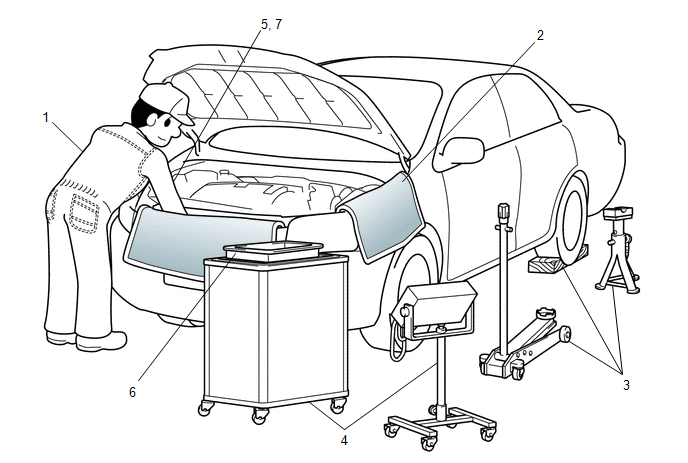

1 | Attire |

|

| 2 |

Vehicle protection | Prepare a grille cover, fender cover, seat cover and floor mat before starting work. |

|

3 | Safety procedures |

|

| 4 |

Preparation of tools and measuring equipment |

Before starting work, prepare a tool stand, SST, measuring equipment, oil, and any replacement parts required. |

|

5 | Removal and installation, disassembly and assembly operations |

|

| 6 |

Removed parts |

|

| 7* |

Checks to perform after work is finished |

|

CAUTION:

*: Be sure to perform these checks properly, not performing these checks properly after finishing work can lead to a serious accident or injury.

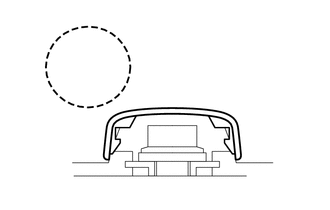

(b) JACKING UP AND SUPPORTING THE VEHICLE

(1) Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the vehicle at the proper locations.

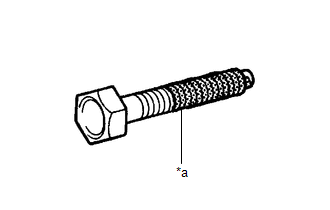

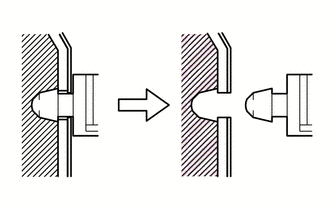

(c) PRECOATED PARTS

|

*a | Seal Lock Adhesive |

(1) Precoated parts are bolts and nuts that are coated with seal lock adhesive at the factory.

(2) If a precoated part is retightened, loosened or moved in any way, it must be recoated with the specified adhesive.

(3) When reusing a precoated part, clean off the old adhesive and dry the part with compressed air. Then apply new seal lock adhesive appropriately to that part.

(4) Some seal lock agents harden slowly. You may have to wait for the seal lock adhesive to harden.

(d) SMALL-HEAD BOLTS

(1) Small-head bolts are bolts with a smaller bolt head than standard bolts with the same thread diameter and flange diameter.

|

*A | Example: M6 Bolt |

|

*a | Ring Mark |

|

*b | Black |

(2) Although the size of the bolt head is smaller than a standard bolt, the tightening torque remains unchanged as the thread diameter and flange diameter are not different. Make sure to tighten all small-head bolts to the correct torque indicated in the repair manual.

(3) As the force applied to the sides of the head of a small-head bolt is higher than that of a standard bolt when the same tightening torque is used, the height of the bolt head has been increased to ensure its strength.

(4) For identification purposes, small-head bolts are black and the bolt head is marked with a ring.

(e) GASKETS

(1) When necessary, use a sealer on gaskets to prevent leaks.

(f) BOLTS, NUTS AND SCREWS

(1) Carefully follow all the specifications for tightening torque. Always use a torque wrench.

(2) Make sure that no foreign matter (burrs, paint, etc.) gets trapped under the heads of the bolts and nuts when tightening them.

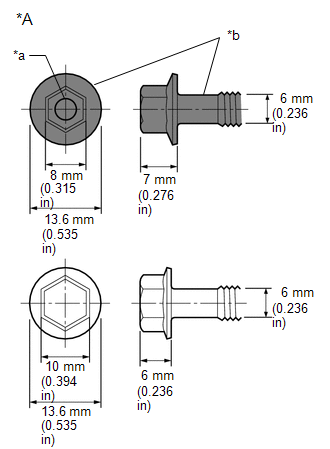

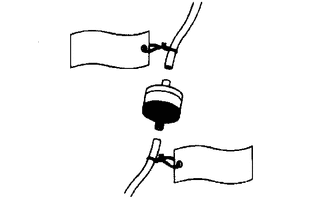

(g) FUSES

|

*a | Incorrect |

|

*b | Correct |

(1) When inspecting a fuse, check that the wire of the fuse is not broken.

(2) If the wire of a fuse is broken, confirm that there are no shorts in its circuit.

(3) When a fuse is replaced, a fuse with the same amperage rating must be used.

|

Illustration | Symbol |

Part Name | Abbreviation |

|---|---|---|---|

|

|

FUSE | FUSE |

|

|

MEDIUM CURRENT FUSE | M-FUSE |

|

|

HIGH CURRENT FUSE | H-FUSE |

|

|

FUSIBLE LINK | FL |

|

|

CIRCUIT BREAKER | CB |

|

|

FUSIBLE LINK | FL |

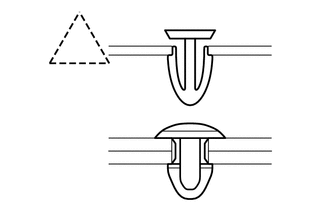

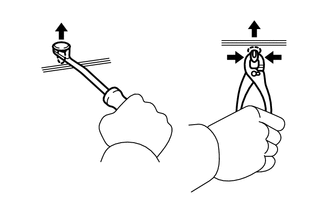

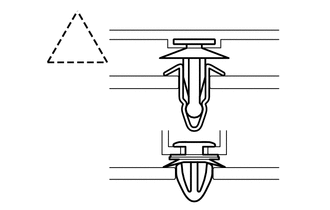

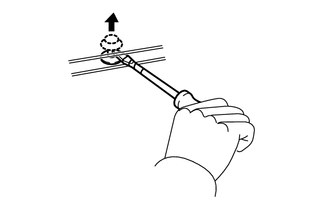

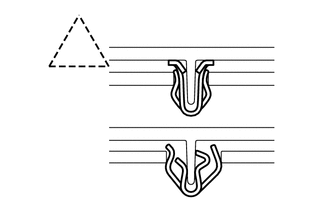

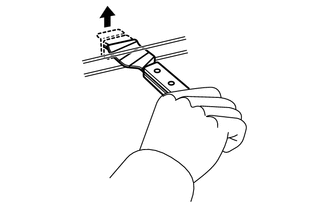

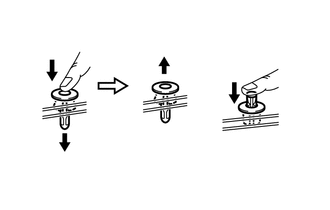

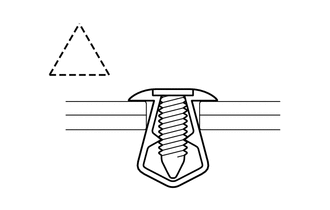

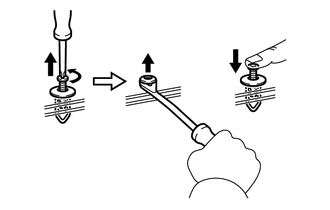

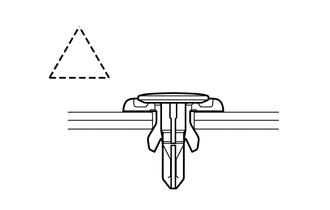

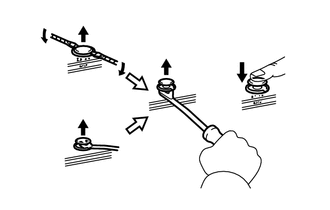

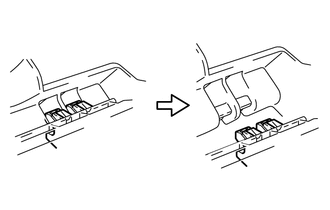

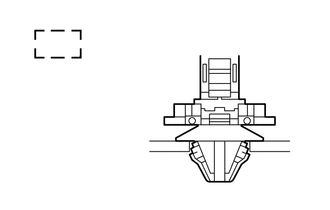

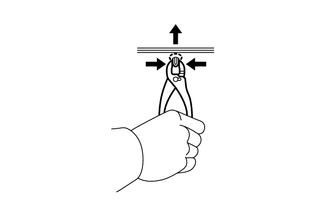

(h) CLIPS

(1) The removal and installation methods of typical clips used for vehicle body parts are shown in the table below.

HINT:

If clips are damaged during a procedure, always replace the damaged clips with new ones.

|

Shape (Example) | Removal/Installation |

|---|---|

| Remove the clips with a clip remover or pliers.  |

| Remove the clips using a clip remover or a screwdriver with its tip wrapped with protective tape.  |

| Remove the clips with a wide scraper to prevent panel damage.  |

| Remove the clips by pushing the center pin through and pulling out the shell.  |

| Remove the clips by unscrewing the center pin and prying out the shell.  |

| Remove the clips by prying out the pin using a screwdriver with its tip wrapped with protective tape and then prying out the shell.  |

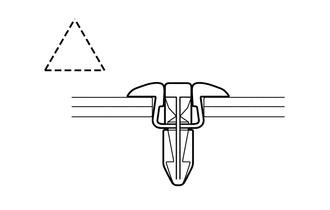

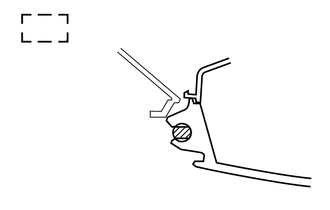

(i) CLAWS

(1) The removal and installation methods of typical claws used for vehicle body parts are shown in the table below.

HINT:

If claws are damaged during a procedure, always replace the cap or cover that has damaged claws with a new one.

|

Shape (Example) | Illustration / Procedures |

|---|---|

| Disengage the claws using a screwdriver with its tip wrapped with protective tape to remove the caps or covers.  |

| Disengage the claws using a screwdriver with its tip wrapped with protective tape to remove the caps or covers.  |

| Disengage the claws using a screwdriver with its tip wrapped with protective tape to remove the caps or covers.  |

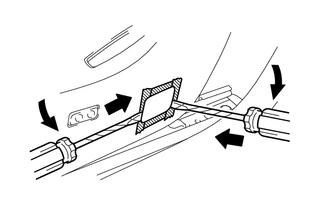

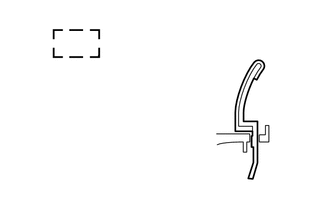

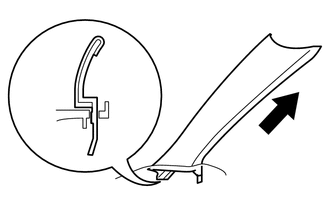

(j) HINGES, GUIDES, CLAMPS, PINS, ETC.

(1) The removal and installation methods of typical hinges, guides, clamps and pins used for vehicle body parts are shown in the table below.

HINT:

If clamps are damaged during a procedure, always replace the cap or cover that has damaged clamps with a new one.

|

Shape (Example) | Removal/Installation |

|---|---|

| Pull away from the pins to disengage.  |

| Disengage the pins by pulling.  |

| Remove the clamps with pliers.  |

| Disengage the pins by pulling.  |

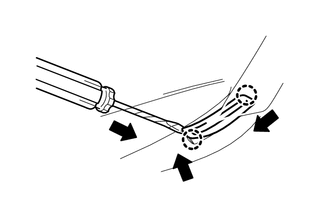

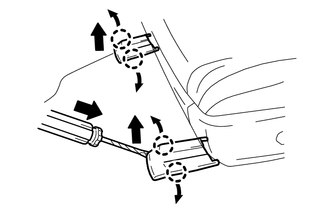

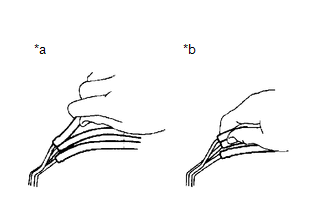

(k) REMOVAL AND INSTALLATION OF VACUUM HOSES

(1) To disconnect a vacuum hose, pull and twist it from the end of the hose. Do not pull it from the middle of the hose as this may damage the hose.

|

*a | Incorrect |

|

*b | Correct |

(2) When disconnecting vacuum hoses, use tags to identify where they should be reconnected.

(3) After completing any hose related repairs, double-check that the vacuum hoses are properly connected. The label under the hood shows the proper layout.

(4) When using a vacuum gauge, never force the hose onto a connector that is too large. If a hose has been stretched, air may leak. Use a step-down adapter if necessary.

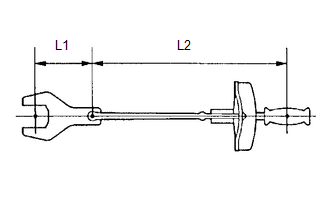

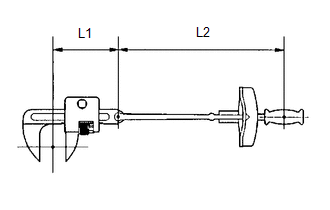

(l) TORQUE WHEN USING TORQUE WRENCH WITH EXTENSION TOOL

(1) Use the formula below to calculate special torque values for situations where SST or an extension tool is combined with a torque wrench.

Formula:

T' = (L2/(L1 + L2))*T

|

T' | Reading of torque wrench (N*m (kgf*cm, ft.*lbf)) |

|

T | Torque (N*m (kgf*cm, ft.*lbf)) |

|

L1 | Length of SST or extension tool (cm (in.)) |

|

L2 | Length of torque wrench (cm (in.)) |

NOTICE:

If an extension tool or SST is combined with a torque wrench and used to tighten to a torque specification in this manual, the actual torque will be excessive and parts will be damaged.

FOR VEHICLES EQUIPPED WITH SRS AIRBAG AND SEAT BELT PRETENSIONER

This vehicle is equipped with a Supplemental Restraint System (SRS).

CAUTION:

- Before performing pre-disposal deployment of any SRS component, review and closely follow all applicable environmental and hazardous material regulations. Pre-disposal deployment may be considered hazardous material treatment.

- Failure to carry out the service operations in the correct sequence could cause the SRS to unexpectedly deploy during servicing and lead to a serious injury. Furthermore, if a mistake is made when servicing the SRS, it is possible that the SRS may fail to operate properly. Before servicing (including removal or installation of parts, inspection or replacement), be sure to read the following section carefully.

(a) GENERAL NOTICE

(1) As malfunctions of the SRS are difficult to confirm, Diagnostic Trouble Codes (DTCs) become the most important source of information when troubleshooting. When troubleshooting the SRS, always check for DTCs before disconnecting the battery.

(2) Work must be started at least 90 seconds after the ignition switch is turned off and the cable is disconnected from the negative (-) battery terminal.

The SRS is equipped with a back-up power source. If work is started within 90 seconds of turning the ignition switch off and disconnecting the cable from the negative (-) battery terminal, the SRS may deploy.

When the cable is disconnected from the negative (-) battery terminal, the clock and audio system memory will be cleared. Before starting work, make a note of the settings of each memory system. When work is finished, reset the clock and audio system as before.

CAUTION:

Never use a back-up power source (battery or other) to avoid clearing the system memory. The back-up power source may inadvertently power the SRS and cause it to deploy.

(3) If the vehicle has been involved in a minor collision where the SRS does not deploy, the steering pad, front passenger airbag assembly, knee airbag assembly, curtain shield airbag assemblies, seat side airbag assemblies and seat outer belt assemblies should be inspected before further use of the vehicle.

(4) Never use SRS parts from another vehicle. When replacing parts, use new ones.

(5) Before performing repairs, remove the airbag sensor assemblies if impacts are likely to be applied to the sensor during repairs.

(6) Never disassemble and attempt to repair any of the airbag sensor assemblies or SRS parts.

- Steering pad

- Front passenger airbag assembly

- Knee airbag assembly

- Curtain shield airbag assembly

- Seat side airbag assembly

- Seat outer belt assembly

(7) Replace the airbag sensor assemblies and the airbag assemblies if: 1) damage has occurred from being dropped, or 2) cracks, dents or other defects in the case, bracket or connector are present.

(8) Do not directly expose the airbag sensor assemblies or airbag assemblies to hot air or flames.

(9) Use a voltmeter/ohmmeter with high impedance (minimum = 10 kΩ) for troubleshooting electrical circuits.

(10) Information labels are attached to the SRS components. Follow the instructions on the labels.

(11) After work on the SRS is completed, check the SRS warning light.

(b) SPIRAL CABLE

(1) The steering wheel must be fitted correctly to the steering column with the spiral cable at the neutral position. Otherwise, cable damage and other problems may occur. Refer to the information about correct installation of the steering wheel.

(c) STEERING PAD

(1) Always place a removed or new steering pad with the deployment surface facing upward. Placing the steering pad with the deployment surface facing downward could cause a serious accident if the airbag deploys. Also, do not place anything on top of the steering pad.

(2) Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

(3) Grease or detergents of any kind should not be applied to the steering pad.

(4) Store the steering pad in an area where the ambient temperature is below 93