Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during brake master cylinder sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|

Disconnect cable from negative battery terminal |

Perform steering sensor zero point calibration |

Lane tracing assist system |

.gif) |

|

Pre-collision system |

|

Memorize steering angle neutral point |

Parking assist monitor system |

.gif) |

|

Panoramic view monitor system |

.gif) |

CAUTION / NOTICE / HINT

NOTICE:

Make sure to release vacuum from the brake booster assembly before removing the brake master cylinder sub-assembly from the brake booster assembly.

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here .gif)

2. REMOVE BATTERY

for A25A-FKS: Click here .gif)

for 2GR-FKS: Click here

.gif)

3. DRAIN BRAKE FLUID

NOTICE:

If brake fluid leaks onto any painted surface, immediately wash it off.

4. REMOVE BRAKE MASTER CYLINDER SUB-ASSEMBLY

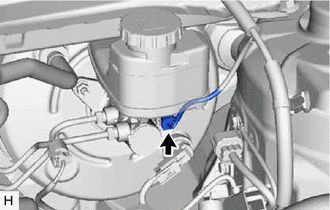

| (a) Disconnect the connector from the brake master cylinder sub-assembly. |

|

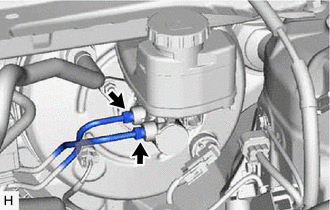

| (b) Using a union nut wrench, disconnect the 2 brake lines from the brake master cylinder sub-assembly.

NOTICE:

- Do not damage or deform the brake lines.

- Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

| |

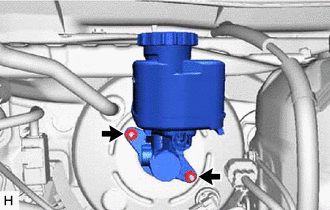

| (c) Remove the 2 nuts and brake master cylinder sub-assembly from the brake booster assembly.

NOTICE:

- The brake master cylinder sub-assembly requires careful handling. Do not drop or subject the brake master cylinder sub-assembly to any impact. Do not reuse a brake master cylinder sub-assembly that has been dropped.

- Do not hold the brake master cylinder sub-assembly by the master cylinder piston. Hold the brake master cylinder sub-assembly by its body or its reservoir when carrying it.

- Do not pull out the master cylinder piston.

- Do not strike or pinch the master cylinder piston, or cause any damage to the master cylinder piston by any other means.

- When installing the brake master cylinder sub-assembly to the brake booster assembly, or when removing the brake master cylinder sub-assembly from the brake booster assembly, make sure that the brake master cylinder sub-assembly is kept horizontal or with its tip facing downward (the master cylinder piston is facing upward) to prevent the master cylinder piston from falling out.

- Do not allow any foreign matter to contaminate the master cylinder piston. If any foreign matter gets on the master cylinder piston, remove it by using a piece of new and dry cloth. Do not use water or detergent. Then apply an even layer of lithium soap base glycol grease around the circumference (sliding part) of the master cylinder piston.

- Do not use any other types of grease.

- Make sure to release vacuum from the brake booster assembly before removing the brake master cylinder sub-assembly from the brake booster assembly.

| |

5. REMOVE BRAKE MASTER CYLINDER O-RING

(a) Remove the brake master cylinder O-ring from the brake master cylinder sub-assembly.

READ NEXT:

DISASSEMBLY PROCEDURE 1. REMOVE BRAKE MASTER CYLINDER STRAIGHT PIN

(a) Secure the brake master cylinder sub-assembly in a vise. NOTICE:

Place aluminum plates on the vise to prevent damage to the b

INSPECTION PROCEDURE 1. INSPECT AND ADJUST BRAKE BOOSTER PUSH ROD

NOTICE: Make the adjustment with no vacuum in the brake booster assembly. (Depress the brake pedal several times with the engine sto

REASSEMBLY PROCEDURE 1. INSTALL BRAKE MASTER CYLINDER RESERVOIR STRAINER

2. INSTALL BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY 3. INSTALL MASTER CYLINDER RESERVOIR GROMMET

(a) Apply a lig

SEE MORE:

ComponentsCOMPONENTS ILLUSTRATION

*1 STEERING SENSOR

*2 SPIRAL CABLE SUB-ASSEMBLY RemovalREMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replac

ON-VEHICLE INSPECTION CAUTION / NOTICE / HINT

CAUTION: To prevent injury due to contact with an operating V-ribbed belt or cooling fan, keep your hands and clothing away from the V-ribbed belt and cooling fans when working in the engine compartment with the engine running or the engine switch on

.gif)

.gif)

.gif)