Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during front crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

| Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision System | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic view monitor system |

| ||

|

Replacement of ECM | Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

| |

|

Gas leak from exhaust system is repaired |

Inspection After Repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM |

Code registration |

|

|

|

Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Replacement of front bumper assembly |

Front television camera view adjustment |

Panoramic view monitor system |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

| ||

| Front wheel alignment adjustment |

|

|

|

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

Click here

.gif)

.gif)

2. REMOVE V-RIBBED BELT

Click here

.gif)

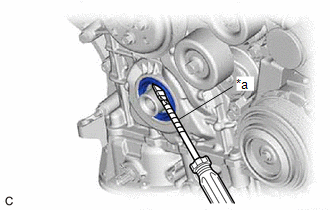

3. REMOVE CRANKSHAFT PULLEY

(a) Using SST to hold the crankshaft pulley, loosen the crankshaft pulley set bolt. Further loosen the crankshaft pulley set bolt until 2 or 3 threads remain screwed into the crankshaft.

|

*a | Hold |

.png) |

Turn |

SST: 09213-70011

09213-70020

SST: 09330-00021

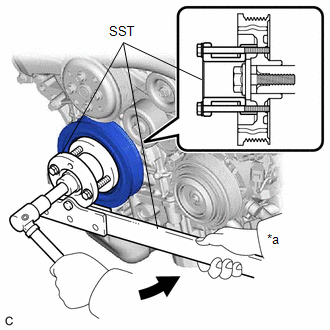

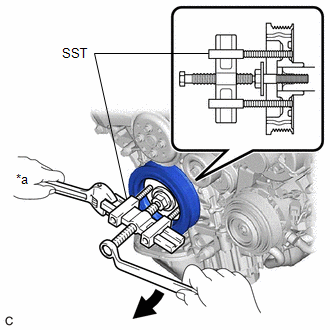

(b) Using SST, remove the crankshaft pulley set bolt and crankshaft pulley.

|

*a | Hold |

.png) |

Turn |

SST: 09950-50013

09951-05010

09952-05010

09953-05020

09954-05021

4. REMOVE TIMING CHAIN CASE OIL SEAL

| (a) Using a screwdriver with its tip wrapped with protective tape, pry out the timing chain case oil seal. NOTICE: After removal, check the crankshaft for damage. If it is damaged, smooth the surface with 400-grit sandpaper. |

|