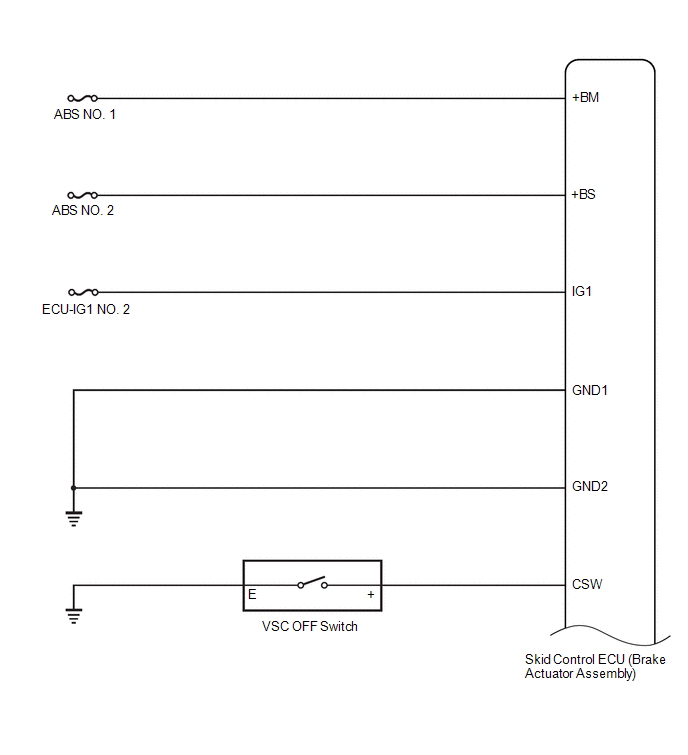

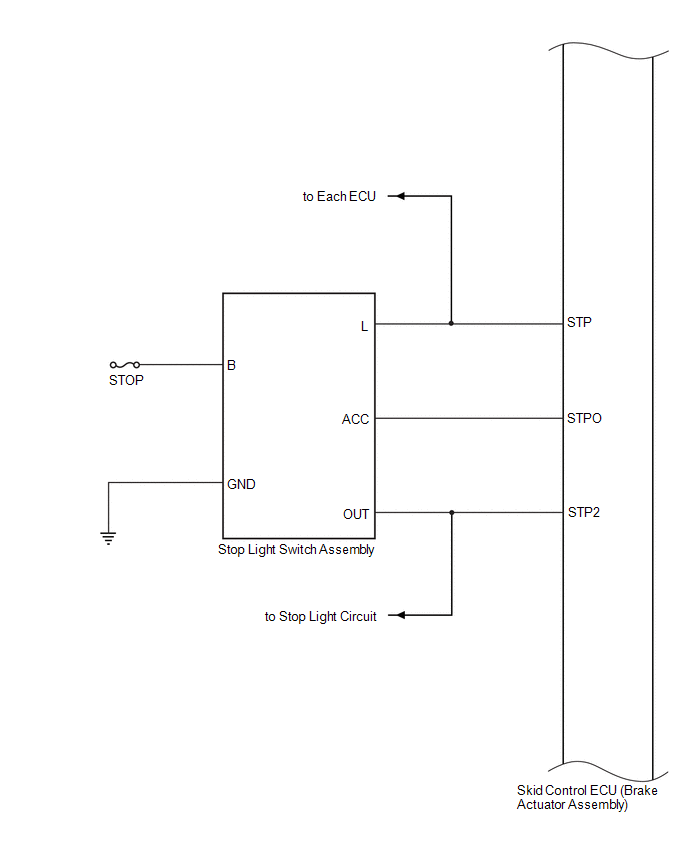

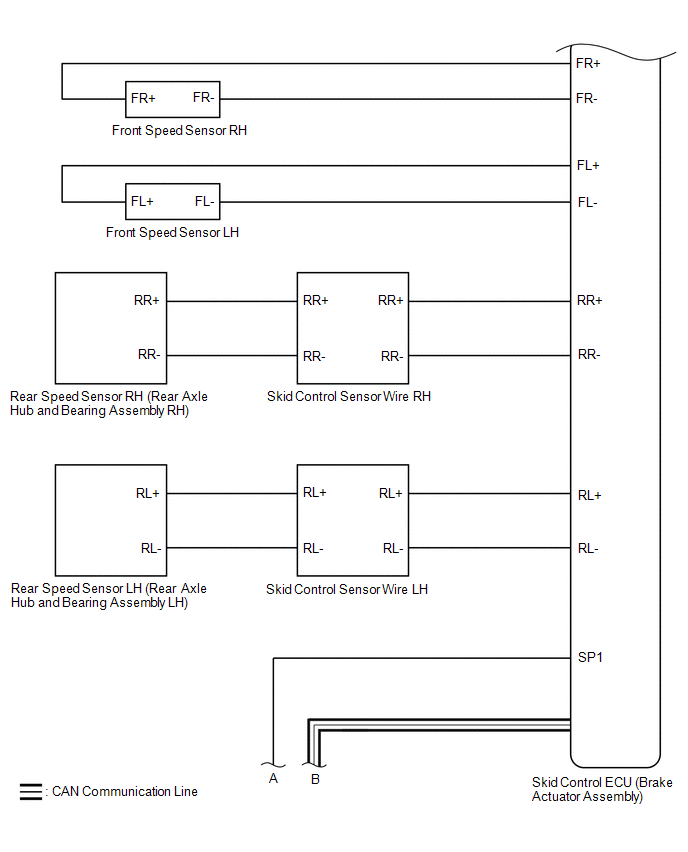

Toyota Camry (XV70): System Diagram

SYSTEM DIAGRAM

.png)

.png)

|

Transmitting ECU (Transmitter) |

Receiving ECU | Signal |

Communication Method |

|---|---|---|---|

|

Skid control ECU (brake actuator assembly) |

Steering angle sensor | Steering angle sensor request signal |

CAN communication line |

|

Steering angle sensor |

Skid control ECU (brake actuator assembly) |

Steering angle sensor signal |

CAN communication line |

|

Skid control ECU (brake actuator assembly) |

Yaw rate and acceleration sensor (airbag sensor assembly) |

Yaw rate and acceleration request signal |

CAN communication line |

|

Yaw rate and acceleration sensor (airbag sensor assembly) |

Skid control ECU (brake actuator assembly) |

Yaw rate and acceleration signal |

CAN communication line |

|

Skid control ECU (brake actuator assembly) |

ECM |

| CAN communication line |

|

ECM | Skid control ECU (brake actuator assembly) |

| CAN communication line |

|

Skid control ECU (brake actuator assembly) |

Power steering ECU (rack and pinion power steering gear assembly) |

| CAN communication line |

|

Main body ECU (multiplex network body ECU) |

Skid control ECU (brake actuator assembly) |

Parking brake switch assembly signal |

CAN communication line |

|

Skid control ECU (brake actuator assembly) |

Combination meter assembly |

| CAN communication line |

|

Airbag sensor assembly |

Skid control ECU (brake actuator assembly) |

Secondary collision brake request signal |

CAN communication line |