Toyota Camry (XV70): Torque Converter And Drive Plate

Inspection

INSPECTION

PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY

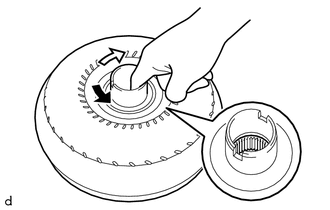

(a) Inspect the one-way clutch. Press on the splines of the stator with a finger and rotate it. Check that it rotates smoothly when turned clockwise and rotates with difficulty when turned counterclockwise.

.png) |

Difficult |

.png) |

Smooth |

If necessary, clean the torque converter assembly and recheck the one-way clutch. Replace the torque converter assembly if the one-way clutch still fails the inspection.

| (b) Inspect the torque converter assembly. If any of the following problems are present, replace the torque converter assembly. Malfunction:

HINT: The sample shows approximately 0.025 liters (0.026 US qts, 0.022 Imp. qts) of ATF in a Petri dish, which has been taken from the removed torque converter assembly. |

|

(c) Replace the ATF in the torque converter assembly.

HINT:

If the ATF is discolored or has a foul odor, stir the ATF in the torque converter assembly and drain it before replacing the ATF.

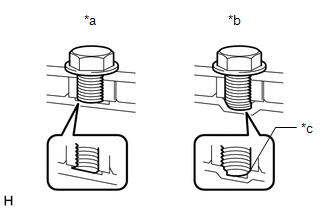

| (d) Prevent deformation of the torque converter assembly and damage to the oil pump gear. NOTICE: Make sure that all of the bolts are the same length and that the specified bolts are used. HINT: If there is any damage to the tip of a bolt for the torque converter assembly or to the bottom of a bolt hole, replace the bolt and torque converter assembly. |

|

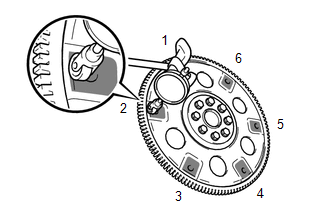

2. INSPECT DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

(a) Check the drive plate and ring gear sub-assembly for damage.

.png) |

Measurement Point |

(b) Set up a dial indicator and measure the runout at the 6 areas on the drive plate and ring gear sub-assembly surface that contact the torque converter clutch assembly.

Maximum Runout:

0.30 mm (0.0118 in.)

HINT:

- If the runout is more than the maximum or the drive plate and ring gear sub-assembly is damaged, replace the drive plate and ring gear sub-assembly.

- If installing a new drive plate and ring gear sub-assembly, confirm that the spacers are oriented properly before tightening the bolts.

Click here

.gif)