Toyota Camry (XV70): Blind Spot Monitor Sensor

Components

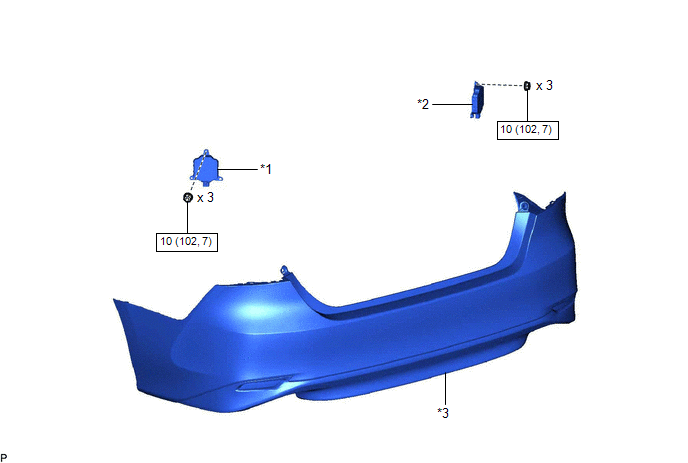

COMPONENTS

ILLUSTRATION

|

*1 | BLIND SPOT MONITOR SENSOR LH |

*2 | BLIND SPOT MONITOR SENSOR RH |

|

*3 | REAR BUMPER ASSEMBLY |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf) : Specified torque |

- | - |

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during blind spot monitor sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Blind spot monitor sensor |

Blind spot monitor beam axis adjustment |

|

|

|

Rear bumper assembly (w/ Parking Support Brake System) |

|

|

|

PROCEDURE

1. REMOVE REAR BUMPER ASSEMBLY

Click here

.gif)

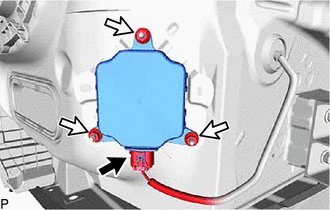

2. REMOVE BLIND SPOT MONITOR SENSOR LH

| (a) Disconnect the connector. |

|

(b) Remove the 3 nuts and blind spot monitor sensor LH.

NOTICE:

Replace the blind spot monitor sensor LH if it has been dropped or subjected to a severe impact.

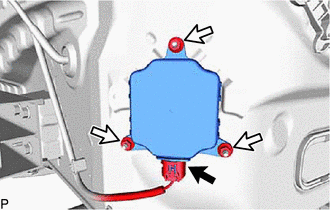

3. REMOVE BLIND SPOT MONITOR SENSOR RH

| (a) Disconnect the connector. |

|

(b) Remove the 3 nuts and blind spot monitor sensor RH.

NOTICE:

Replace the blind spot monitor sensor RH if it has been dropped or subjected to a severe impact.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

- Avoid any impact to the blind spot monitor sensor.

- Do not drop the blind spot monitor sensor. If it is dropped, replace it with a new one.

HINT:

- The blind spot monitor beam axis confirmation is performed to confirm whether the sensor beam axis is correct, and to adjust the beam axis by using a reflector.

- The blind spot monitor sensor installation condition inspection is performed to confirm whether the sensor is perpendicular to the floor surface (+/-2.2