Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT PADDLE SWITCH (TRANSMISSION SHIFT SWITCH ASSEMBLY)

(a) Shift Paddle Switch LH (Transmission Shift Switch Assembly):

| (1) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 (SDN) - 2 (ECC) |

"-" (Down shift) shift paddle switch operated and held |

Below 2.5 Ω | |

"-" (Down shift) shift paddle switch not operated |

1 MΩ or higher | |

1 (SDN) - 3 (ECC1) |

"-" (Down shift) shift paddle switch operated and held |

Below 2.5 Ω | |

"-" (Down shift) shift paddle switch not operated |

1 MΩ or higher | If the result is not as specified, replace the shift paddle switch LH (transmission shift switch assembly). |

|

|

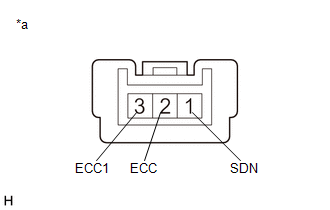

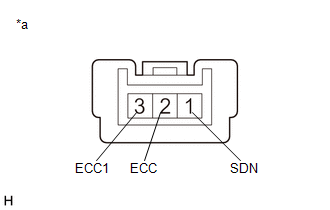

*a | Component without harness connected

(Shift Paddle Switch LH (Transmission Shift Switch Assembly)) | | |

(b) Shift Paddle Switch RH (Transmission Shift Switch Assembly):

| (1) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 (SUP) - 2 (ECC) |

"+" (Up shift) shift paddle switch operated and held |

Below 2.5 Ω | |

"+" (Up shift) shift paddle switch not operated |

1 MΩ or higher | If the result is not as specified, replace the shift paddle switch RH (transmission shift switch assembly). |

|

|

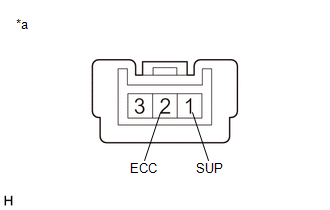

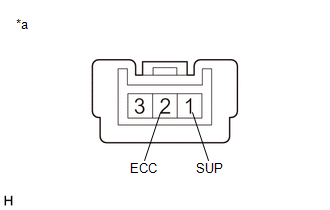

*a | Component without harness connected

(Shift Paddle Switch RH (Transmission Shift Switch Assembly)) | | |

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL NO. 1 SWITCH WIRE

HINT: Perform this procedure only when replacement of the No. 1 switch wire is necessary.

(a) Engage the 2 guides to install the No. 1 switch wi

ComponentsCOMPONENTS ILLUSTRATION

*1 TRANSMISSION REVOLUTION SENSOR (NC)

*2 TRANSMISSION REVOLUTION SENSOR (NT)

*3 SPACER

- -

Tightening torque for

InspectionINSPECTION PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY (a) Inspect the one-way clutch. Press on the splines of the stator with a finger and rotate it. Check that it rotates smoothly whe

SEE MORE:

ON-VEHICLE INSPECTION CAUTION / NOTICE / HINT

CAUTION: To prevent injury due to contact with an operating V-ribbed belt or cooling fan, keep your hands and clothing away from the V-ribbed belt and cooling fans when working in the engine compartment with the engine running or the engine switch on

DESCRIPTION The radio and display receiver assembly, roof console box sub-assembly and telephone microphone assembly are connected to each other using the microphone connection detection signal lines.

This DTC is stored when a microphone connection detection signal line is disconnected.

DTC