Toyota Camry (XV70): Linear Solenoid Power Supply System Malfunction (C120C)

DESCRIPTION

This DTC is output by the 4WD ECU assembly if a malfunction occurs in the linear solenoid power supply system.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

|---|---|---|---|

|

C120C | Linear Solenoid Power Supply System Malfunction |

|

|

|

Vehicle Condition | ||||

|---|---|---|---|---|

|

Pattern 1 | Pattern 2 |

Pattern 3 | ||

|

Diagnosis Condition | When the 4WD relay is on and the voltage at the IG1 terminal is 9.5 V or more |

○ | - |

- |

| When the 4WD relay is on and the voltage at the IG1 terminal is less than 9.5 V |

- | ○ |

- | |

| While the 4WD relay is off |

- | - |

○ | |

|

Malfunction Status | The 4WD relay monitor remains off |

○ | ○ |

- |

| The 4WD relay monitor remains on immediately after the ignition switch is turned to ON |

- | - |

○ | |

|

Detection Time | 1 second or more |

1 second or more | 1 second or more | |

|

Number of Trips | 1 trip |

1 trip | 1 trip | |

HINT:

DTC will be output when conditions for any of the patterns in the table above are met.

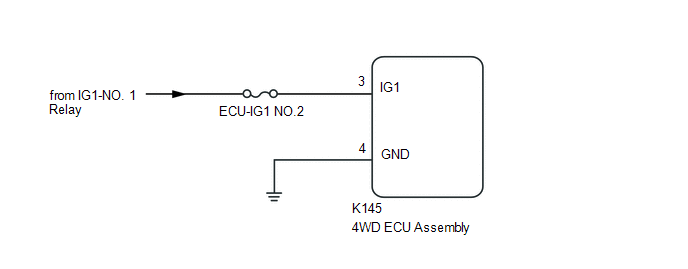

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

| 1. |

CHECK HARNESS AND CONNECTOR (IG1 TERMINAL) |

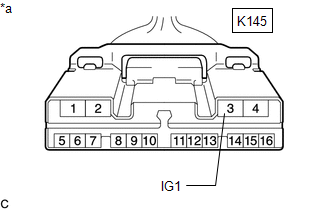

| (a) Disconnect the K145 4WD ECU assembly connector. |

|

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K145-3 (IG1) -Body ground |

Ignition switch ON | 11 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 2. |

CHECK HARNESS AND CONNECTOR (GND TERMINAL) |

(a) Turn the ignition switch off.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K145-4 (GND) -Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

RECONFIRM DTC |

(a) Clear the DTC.

Chassis > Four Wheel Drive > Clear DTCs(b) Turn the ignition switch to ON.

(c) Check that no DTCs other than DTC C120C have been output.

Chassis > Four Wheel Drive > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTCs other than DTC C120C are not output |

A |

| DTCs other than DTC C120C are output |

B |

| A |

.gif) | REPLACE 4WD ECU ASSEMBLY

|

| B |

.gif) | REPAIR CIRCUIT INDICATED BY OUTPUT CODE

|

.gif)

.gif)