Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during propeller with center bearing shaft assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Exhaust system parts |

Inspection after repair |

|

|

CAUTION:

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

.png)

PROCEDURE

1. REMOVE EXHAUST PIPE ASSEMBLY

Click here

.gif)

2. REMOVE FRONT LOWER NO. 1 FLOOR HEAT INSULATOR

Click here .gif)

.gif)

3. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

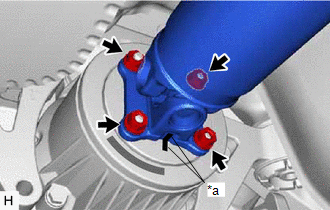

| (a) Put matchmarks on the rear differential carrier assembly and propeller with center bearing shaft assembly. |

|

(b) Remove the 4 nuts and 4 washers.

(c) Using a brass bar and a hammer, separate the propeller with center bearing shaft assembly.

NOTICE:

Use wire or an equivalent tool to keep the propeller with center bearing shaft assembly.

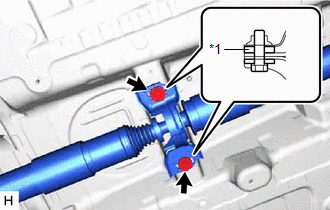

| (d) Remove the 2 bolts and 2 center No. 2 support bearing washers (for rear side). NOTICE: When removing the bolts and center No. 2 support bearing washers, do not apply excessive force to the universal joint. |

|

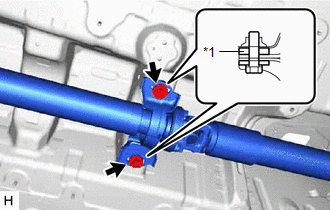

| (e) Remove the 2 bolts and 2 center No. 2 support bearing washers (for front side). NOTICE: When removing the bolts and center No. 2 support bearing washers, do not apply excessive force to the universal joint. |

|

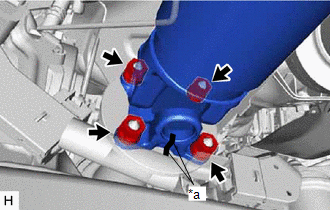

| (f) Put matchmarks on the transfer assembly and propeller with center bearing shaft assembly. |

|

(g) Remove the 4 nuts, 4 washers and propeller with center bearing shaft assembly from the transfer assembly.

NOTICE:

- When removing the propeller with center bearing shaft assembly, do not apply excessive force to the universal joint.

- During and after the removal of the propeller with center bearing shaft assembly, keep the universal joint angle straight (within 15 degrees).