Toyota Camry (XV70): Components

COMPONENTS

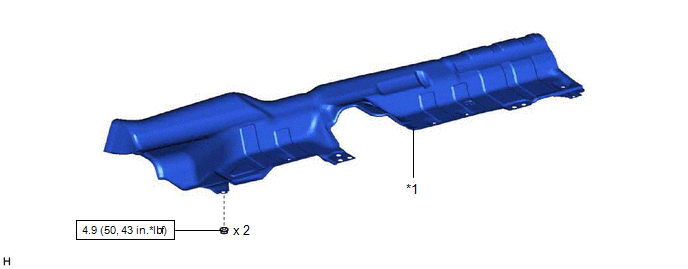

ILLUSTRATION

|

*1 | FRONT LOWER NO. 1 FLOOR HEAT INSULATOR |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

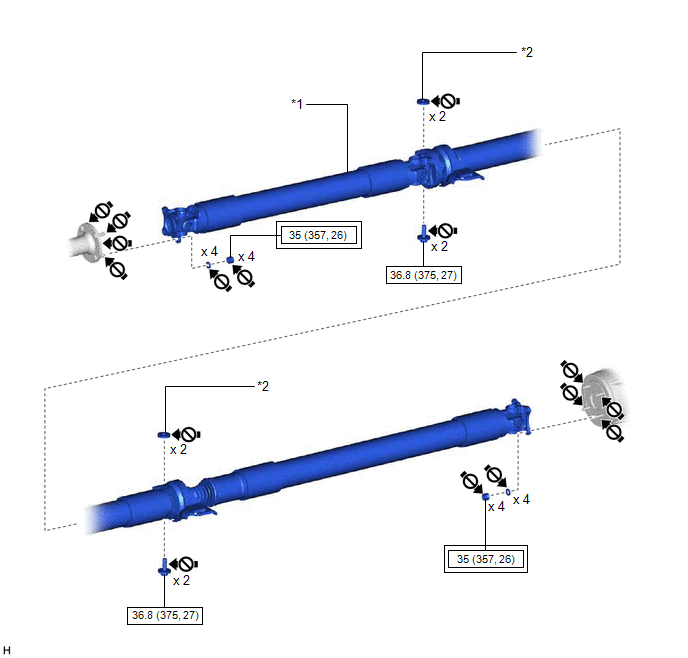

ILLUSTRATION

|

*1 | PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY |

*2 | CENTER NO. 2 SUPPORT BEARING WASHER |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

.png) |

Do not apply lubricants |

- | - |

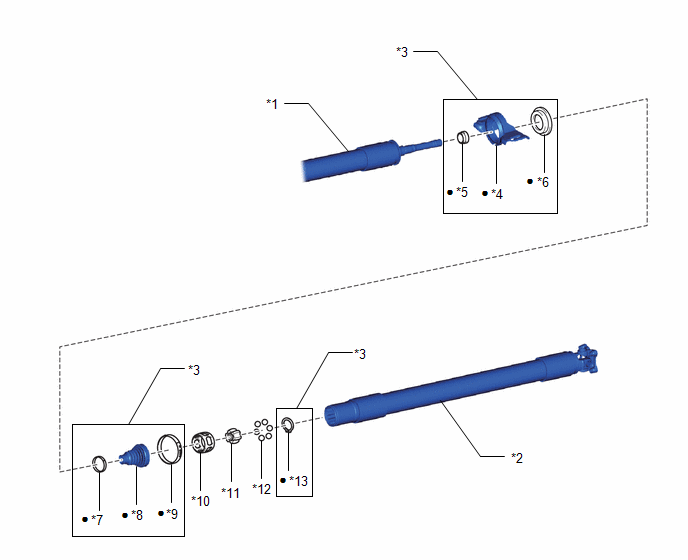

ILLUSTRATION

|

*1 | PROPELLER INTERMEDIATE SHAFT ASSEMBLY |

*2 | REAR PROPELLER SHAFT ASSEMBLY |

|

*3 | UNIVERSAL BOOT KIT |

*4 | CENTER SUPPORT BEARING |

|

*5 | NO. 1 DUST DEFLECTOR |

*6 | FLANGE |

|

*7 | SMALL DIAMETER PROPELLER SHAFT BOOT CLAMP |

*8 | PROPELLER SHAFT BOOT |

|

*9 | LARGE DIAMETER PROPELLER SHAFT BOOT CLAMP |

*10 | BALL CAGE |

|

*11 | INNER RACE |

*12 | BALL |

|

*13 | PROPELLER SHAFT SNAP RING |

- | - |

|

● | Non-reusable part |

- | - |

READ NEXT:

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during p

Disassembly

Disassembly

DISASSEMBLY CAUTION / NOTICE / HINT

NOTICE:

As imbalance affects vibration and noise performance, make sure to ensure correct angular alignment of the following components during installation.

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Using a dial indicator, measure the runout of the rear propeller shaft assembly (for front side).

Maximum Runo

SEE MORE:

Terminals Of Ecu

Terminals Of Ecu

TERMINALS OF ECU DCM (TELEMATICS TRANSCEIVER)

*a to Telephone Antenna (Sub)

*b to GPS Antenna

*c to Telephone Antenna (Main)

- -

Terminal No. (Symbol) Wiring Color

Terminal Description Condition

Specified Condition

K141-1 (USB-)

How To Proceed With Troubleshooting

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the navigation system.

*: Use the Techstream.

PROCEDURE

1. VEHICLE BROUGHT TO WORKSHOP

NEXT

2.

CUSTOMER PROBLEM ANALYSIS

When troubleshooting, check th

© 2023-2025 Copyright www.tocamry.com